NEWS

NEWS

NEWS

NEWS

NEWS

NEWS

![]() The testing of medical procedures and medication is important as it determines its effectiveness and helps scientists to learn about their side effects. But testing on animals is often considered to be morally wrong, and sometimes its illegal. Testing on humans can be acceptable, though it’s quite hard to find subjects willing to go through various procedures simultaneously. So what are scientists and researchers to do? Why, they simply put a human-on-a-chip :)

The testing of medical procedures and medication is important as it determines its effectiveness and helps scientists to learn about their side effects. But testing on animals is often considered to be morally wrong, and sometimes its illegal. Testing on humans can be acceptable, though it’s quite hard to find subjects willing to go through various procedures simultaneously. So what are scientists and researchers to do? Why, they simply put a human-on-a-chip :)

Gone are the days when replicating a human organ was something only found in sci-fi movies or books. That is now a reality and many labs and research facilities are already making use of human-on-a-chip technology.

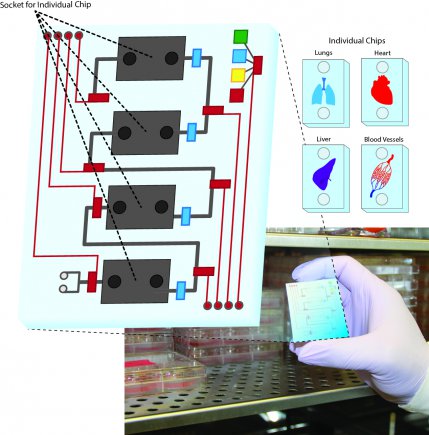

Though the name suggests that there is actually human implanted onto a microchip, it is not an actual human, more like a sample of an organ that is able to perform its function in a controlled environment. Also, the organ is not an actual organ, more like a tissue sample of that organ, or a miniature version of that organ, depending on the lab and what the researchers need. The samples are obtained via Bioprinting or 3D printing, using live undifferentiated cells or stem cells, to create the tissue which will function just as human organs such as the heart, liver, lungs, and blood vessels do. The cells are printed on hydrogel-based scaffolds and the cells are connected to each other by microfluidics, tiny micro channels that functions like blood vessels.

The size of the human-on-a-chip is comparable to a thumb drive, which makes it easier to use in labs, instead of using live people or animals.

The technique will help labs in producing vaccines or medications without having to use real live humans as test subjects. Though this will be greatly beneficial in the healthcare field, the initiative has more use cases, such as chemical warfare.

Fortunately, the Defense Threat Reduction Agency is not using human-on-a-chip to find out how to kill people with chemical weapons. Rather, it’s funding a five-year research project at the U.S. Army Edgewood Chemical Biological Center (ECBC) that aims to create a platform of in vitro human organ constructs in communication with each other, as well as assess the effectiveness and toxicity of drugs in a way that is relevant to humans’, and their ability to process these drugs.

“Today, the use of stem cells in our research program is moving us toward that goal,” Harry Salem, Ph.D., ECBC’s chief scientist for Life Sciences, said.

“Here at ECBC, the screening models will be used to assess the efficacy and safety of medical mitigation procedures and countermeasures for the soldier and the nation as a whole.”

The US Department of Defense also recently invested $24 million in the new technology.

The Wake Forest Institute for Regenerative Medicine in North Carolina developed the bioprinter and was the first to combine several organs on the same chip, which shows how a human body reacts to chemical toxins or biologic agents.

Biochemical agents can wipe out an entire population in as short as a month, so the interest in technology that could help in defending against these weapons is significant. By using these organoids or human-on-a-chip, scientists can get the most accurate results since they are basically testing on humans. Unlike with testing on animals, where sometimes they get positive results, when tested on humans the results are different.

3D printers have come a long way from being bulky printers that takes hours or even days to print a small objects. Today, we have 3D desktops printers that can print the same small objects in just a few minutes, as well as far more complex things like an affordable yet highly functional prosthetic limb.

There’s a chance that in the future, humans would no longer need organ donors – spare organs could literally be ‘printed’ in a matter of a few hours. Though that would mean a way to extend people’s lives, it’s still probably decades away from being a reality, as printing a miniature heart or kidney, the size of a biscuit, already takes 30 minutes. Printing a full scale organ, with all the complex structures could take days or even weeks.

THANK YOU