NEWS

NEWS

NEWS

NEWS

NEWS

NEWS

The field of robotics has seen incredible advancements over the last few decades, and today they are used for everything from industrial manufacturing to vacuuming your floor and scaring your dog. But even with all of these advancements, robots tend to be made of rigid structures and fixed joints that are only capable of certain movements.

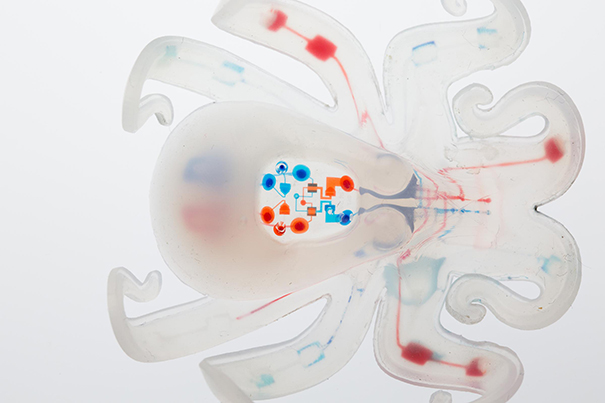

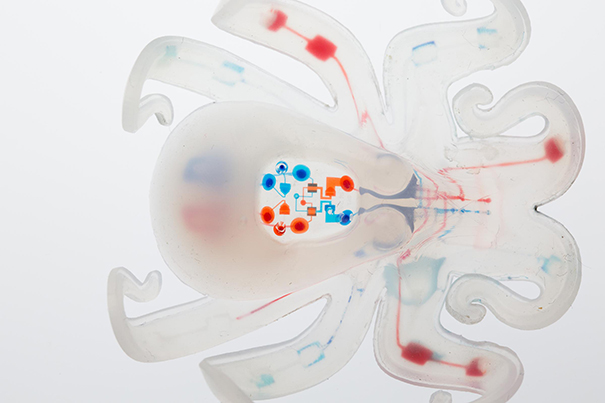

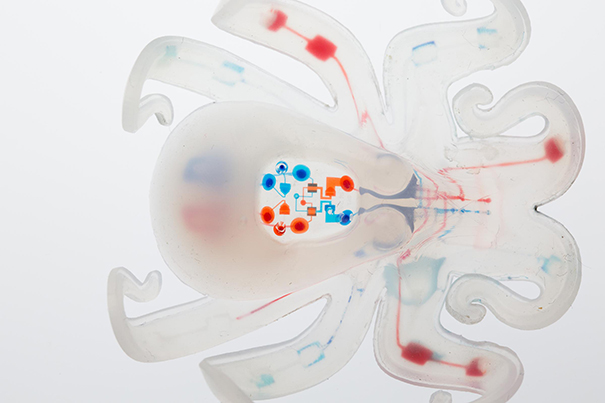

That could soon change thanks to a new robot created by engineers from Harvard University. The new robot, dubbed “Octobot,” is a small, octopus-like autonomous robot that its creators say is “the first entirely soft, autonomous robot,” and it could have major implications for the future of robotics and automation.

Octobot is special in a number of ways, including the fact that it is made from a soft silicone rubber rather than rigid metal or plastic. Soft robots are nothing new, but previous examples have been only partially soft, as they still contained batteries and circuit boards that were not flexible. Octobot is different because it is entirely soft, including its internal components. This allows Octobot to move in ways that would be impossible for traditional robot cannot.

“One longstanding vision for the field of soft robotics has been to create robots that are entirely soft, but the struggle has always been in replacing rigid components like batteries and electronic controls with analogous soft systems and then putting it all together,” said Robert Wood, a professor of engineering and applied sciences at Harvard and one of the lead researchers on the project. “This research demonstrates that we can easily manufacture the key components of a simple, entirely soft robot, which lays the foundation for more complex designs.”

The researchers managed to create a non-rigid power source using a chemical reaction between hydrogen peroxide and platinum, which is controlled by a “microfluidic logic circuit” that regulates when the hydrogen peroxide can decompose to gas.

Octobot’s external structure is a product of 3D printing, which allowed the Harvard researchers to create the robot’s unusual body style.

“Through our hybrid assembly approach, we were able to 3-D print each of the functional components required within the soft robot body, including the fuel storage, power, and actuation, in a rapid manner,” said Jennifer A. Lewis, a professor of biology-inspired engineering at Harvard and the other lead researcher on the Octobot project. “The octobot is a simple embodiment designed to demonstrate our integrated design and additive fabrication strategy for embedding autonomous functionality.”

So what is the point of creating an autonomous soft robot in the first place? Aside from an impressive feat of engineering, Octobot could represent a new type of robot with a wide range of practical uses, particularly in cases where it would need to safely operate around people. Soft robots are able to handle delicate tasks that would be difficult for traditional robots, and some existing examples are used to sort produce without damaging it. With the ability to create autonomous soft robots, those fruit-sorting robots could move out of the factories and into the fields, where they would be able to pick the fruit directly.

Of course, Octobot is a small and incredibly simple robot, so it could be some time before we see more complex examples of what this technology can do, but Ryan Truby, a graduate student and co-author on the Octobot research paper, says that the robot’s design is a sign of things to come.

“This research is a proof of concept,” Truby said. “We hope that our approach for creating autonomous soft robots inspires roboticists, material scientists, and researchers focused on advanced manufacturing.”

You can watch a brief video of Octobot’s design process below:

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.