INFRA

INFRA

INFRA

INFRA

INFRA

INFRA

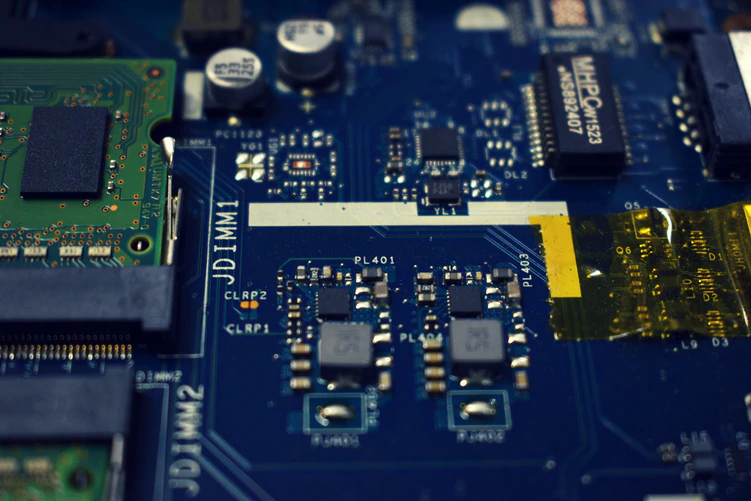

Amid a global chip shortage, Taiwan Semiconductor Manufacturing Co. Ltd. has announced plans to invest $100 billion over three years to expand its production capacity.

TSMC detailed the plan in a letter to clients that was obtained by Bloomberg late Wednesday. According to the letter, TSMC, the world’s leading maker of chips for other companies, will spend the $100 billion allocated for the initiative on two main items: scaling up its manufacturing operations and funding the development of new chip technologies.

Discussing the current state of its manufacturing operations, the company reportedly told clients that its chip plants have been operating at “over 100% utilization” amid surging orders. To address the demand, TSMC said it will build multiple new semiconductor plants around the globe. It intends to hire thousands of new workers to support the effort.

TSMC previously announced plans for a $12 billion plant in Arizona that will make chips based on a five-nanometer manufacturing process, which represents the cutting edge of commercial semiconductor fabrication. According to Nikkei Asia, the company is building a plant in Taiwan that will use an even more advanced three-nanometer process currently still in development.

The part of the $100 billion investment that will go toward engineering new chip technologies will presumably be spent at least in part on bringing the three-nanometer process online. TSMC provided an update about the effort last August. The company said that it was expecting the new process to provide a 10% to 15% speedup for clients’ chips or, alternatively, a 25% to 30% reduction in power requirements at the previous performance levels.

TSMC is reportedly aiming to begin mass-producing three-nanometer chips in the second half of 2022. The only other industry player said to be looking to introduce three-nanometer products in the same time frame is Samsung Electronics Co. Ltd., which in 2019 announced a similar plan to invest more than $100 billion into its chip operations. That sum is set to be spent over a decade.

Rumors suggest that the new chip plant Samsung is looking to build in Texas may eventually use a three-nanometer process. Alongside the surging global demand for processors, the competition TSMC faces from the South Korean electronics giant may have also been a factor behind the supersized price tag of its newly announced chip investment plan.

Because of the central role TSMC plays in the electronics supply chain, the initiative represents a significant development for the entire tech industry. TSMC makes Qualcomm Inc. mobile systems-on-chip, Advanced Micro Systems Inc. central processing units and countless other semiconductor products. Those products, in turn, form the basic building blocks of systems ranging from smartphones to the servers powering the industry’s leading public clouds.

TSMC’s planned investment is also good news for companies outside the tech industry. Manufacturers, including carmakers, increasingly incorporate computing hardware into their products to deliver more advanced features to customers. The auto sector is one of the industries most heavily affected by the current chip shortage, with carmakers such as Ford Motor Co. having had to reduce production because of a lack of parts.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.