INFRA

INFRA

INFRA

INFRA

INFRA

INFRA

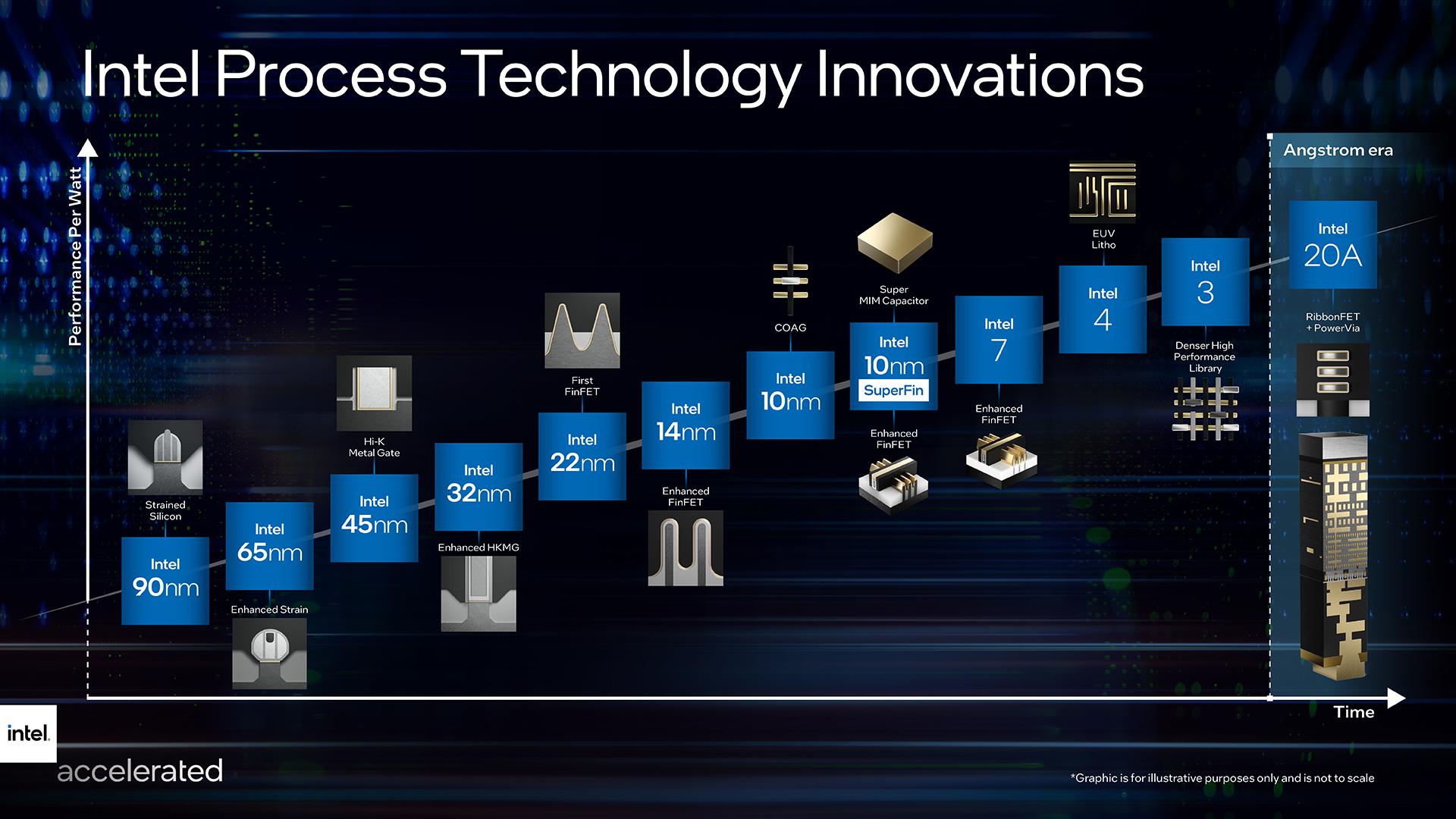

Iconic computer chipmaker Intel Corp. is reimagining how it brands its future semiconductor innovations, announcing today one of its most ambitious roadmaps ever, with new chip and packaging technologies that it says will help it reclaim its leadership of the processor market by 2025.

Intel Chief Executive Pat Gelsinger (pictured) said at the company’s Intel Accelerated event today that its future products will no longer use the old nanometer-based naming convention for its new innovations. Rather, it’s moving to a new nomenclature that Gelsinger said would provide “a more accurate view of process nodes across the industry.”

“We are accelerating our innovation roadmap to ensure we are on a clear path to process performance leadership by 2025,” Gelsinger said at the livestreamed event. “We are leveraging our unparalleled pipeline of innovation to deliver technology advances from the transistor up to the system level. Until the periodic table is exhausted, we will be relentless in our pursuit of Moore’s Law and our path to innovate with the magic of silicon.”

The new naming scheme means that what would have been Intel’s third-generation 10nm chips will now be called “Intel 7.” Although at first glance that might look like a cheap way for Intel to position its upcoming 10-nanometer chips as being more competitive next to its rivals’ 7nm products, analysts say that’s not really the case.

It’s well-known, for example, that Intel’s 10nm chips are more or less on a par with Advanced Micro Devices Inc.’s 7nm processors, since they use similar production technologies and offer a comparable transistor density.

“Intel has been more honest than TSMC and Samsung on node naming,” said analyst Patrick Moorhead of Moor Insights & Strategy. “I think Intel’s renaming is fair and credible in the context of what TSMC and Samsung are doing. There is no industry standard way yet to compare these nodes.”

The Intel 7 products are expected to show up soon, Intel said, with the previously previewed Alder Lake processors set to arrive in consumer products at the end of 2021, and the Sapphire Rapids data center chips due in 2022. Those chips are the successor to Intel’s 10nm SuperFin, second-generation 10nm silicon.

The company said today Intel 7 will come with a performance-per-watt improvement of about 10% to 15%. Alternatively it will be able to deliver more power efficiency and greater battery life if hardware makers choose not to eke out the extra performance.

The second new product on Intel’s roadmap is Intel 4, which is the architecture that would have been labeled a 7nm process under the old naming convention. Intel suffered a big loss to its prestige when it had to push back the launch of these chips from its original 2021 release date to 2023, but the company is sticking to its guns now.

Intel 4 is the next major technology jump and will see the company use extreme ultraviolet lithography to manufacture the processors. EUV is already used on rival Samsung Electronics Co. Ltd.’s and Taiwan Semiconductor Manufacturing Co.’s 5nm products.

Intel said Intel 4 will result in a transistor density of about 200-250 million transistors per mm², compared to about 171.30 million transistors per mm² on TSMC’s current 5nm node. That will translate to a performance-per-watt improvement of about 20% over its current generation silicon. Production of Intel 4 is slated for the second half of next year, with the first products expected to go on sale in 2023.

Next on Intel’s roadmap is Intel 3, which will use the same architecture as Intel 4 but offer various optimizations that improve its performance. The Intel 3 chips should go into production in the second half of 2023, with products arriving some time in 2024.

Moving on, and this is where things get interesting. Intel said it will enter what it calls the “Ångstrom era” of chip design. Ångstroms are units of measurement smaller than nanometers, with 20Å said to be equal to 2nm. The first chip to be measured in Ångstroms will be the Intel 20A, featuring a brand new architecture called RibbonFET.

It’s a fundamentally new transistor technology that will enable greater density and smaller sizes, Gelsinger said. It will also incorporate a new “PowerVia” technology that makes it possible for the silicon wafers to be powered from the back of the chip, instead of being routed to the front.

Gelsinger said during the event that Qualcomm Inc. will be one of its first customers to use the Intel Ångstrom 20A process service when production begins to ramp up in 2024.

Intel also provided a peek at what lies beyond Intel 20A, with Intel 18A, which is said to be on track for an early 2025 production date. The Intel 18A chips will feature refinements to RibbonFET that will bring about another major advance in transistor performance. They will be manufactured using a new High NA EUV technology that’s said to be the next generation of EUV.

Analyst Charles King of Pund-IT Inc. told SiliconANGLE that it’s important to note that the nanometer process terminology focuses on just one aspect of semiconductor design and doesn’t accurately reflect the innovations and improvements in new chip technologies.

“What’s most important for customers and end users is a steady, dependable deliver of new and improved silicon capabilities,” King said. “If Intel can deliver on what Gelsinger has promised will be in Intel 20A, the company should continue its longstanding market leadership and regain its position as a leading innovator in semiconductor development and manufacturing.”

Of course, it’s important to remember that Intel is still coming at this from behind its competitors, so it will struggle to get ahead anytime soon, said analyst Holger Mueller of Constellation Research Inc. “It’s good to see Intel being realistic and planning for the next couple of years to bank on 10nm,” he said. “On the flip side, if its competitors can show higher efficiency with their 7nm chips, it will be more blues for Intel in the near term.”

Whether Intel can catch up and reassume leadership of the semiconductor space remains to be seen. A lot will depend on it avoiding the manufacturing snags and delays that held up its 10nm and 7nm processes, but it’s clear enough from today’s ambitious plans that Intel isn’t going down without a fight.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.