INFRA

INFRA

INFRA

INFRA

INFRA

INFRA

Taiwan-based GlobalWafers Co., a major supplier of the silicon wafers used to make central processing units and other chips, plans to build a $5 billion silicon wafer plant in Sherman, Texas.

The Wall Street Journal reported the plan today.

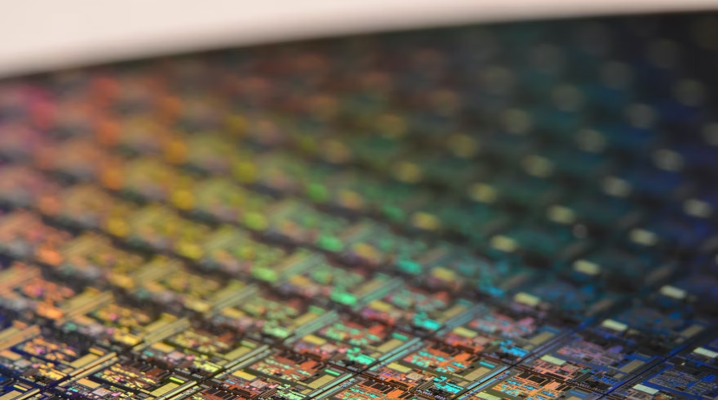

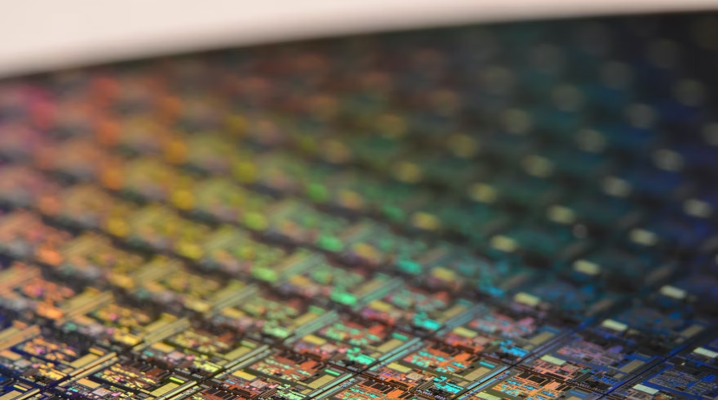

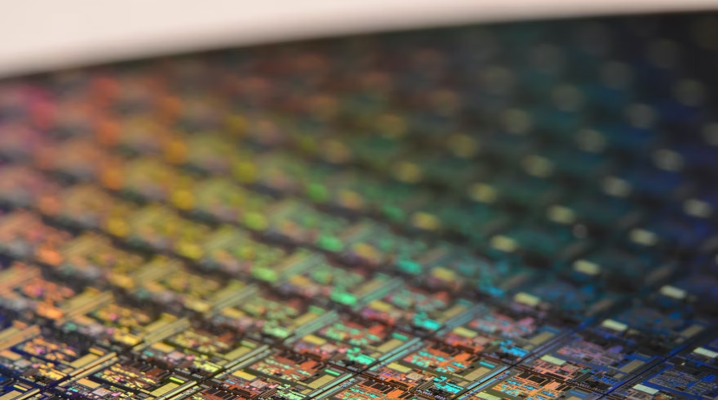

A wafer is a semiconducting disc made largely of silicon that is used to manufacture chips. The chip manufacturing process involves carving transistor-shaped patterns into the wafer using beams of light, which are in turn generated by specialized machines that can cost as much as $200 million apiece. Once the transistors are ready, the wafer is broken up into upwards of dozens of individual processors.

Wafers are usually made from a type of sand called silica sand that contains silicon. One common manufacturing approach is to melt the sand and turn it into a silicon cylinder, or ingot as it’s known in the semiconductor industry. This cylinder is then turned into wafers with the help of specialized equipment.

The $5 billion wafer manufacturing facility that GlobalWafers plans to open in Sherman will create as many as 1,500 jobs, the Journal reported today. It will help increase the available wafer manufacturing capacity in the U.S. According to today’s report, it’s believed that existing U.S. wafer plants will be capable of meeting only 20% of domestic demand by 2025.

GlobalWafers told the Journal that the new facility will “require financial incentives included in the Chips Act.” The Chips Act, which was passed by the Senate in 2021, allocates $52 billion in funding to the semiconductor industry. The House this year also passed a bill that would provide $52 billion in funding for the semiconductor industry, but lawmakers haven’t yet resolved the differences between the two legislative proposals.

The GlobalWafers facility is set to join an array of other multibillion-dollar plants being built in the U.S. by semiconductor companies. Taiwan Semiconductor Manufacturing Co. Ltd. last year started construction on a $12 billion fab in Arizona, while Samsung Electronics Co. Ltd. plans to build a $17 billion fab in Texas. Intel Corp. in turn, plans to build four new chip fabs that are expected to cost more than $40 billion collectively.

Intel has indicated that it could further grow its U.S. manufacturing network in the future. Two of the four chip fabs that the company plans to build will be located on a nearly 1,000-acre “megasite” near Columbus, Ohio. Intel has estimated that it could potentially invest as much as $100 billion over the next decade in the megasite, which is theoretically capable of accommodating up to eight fabs.

THANK YOU