INFRA

INFRA

INFRA

INFRA

INFRA

INFRA

Three SpaceX Corp. alumni who helped the rocket company develop optical communications for its Starlink satellite Wi-Fi service have raised millions of dollars to commercialize that technology for data centers.

Mesh Optical Technologies, co-founded by its Chief Executive Travis Brashears, President Cameron Ramos and Vice President of Product Serena Grown-Haeberli, said today it has raised $50 million in a Series A funding. The round was led by Thrive Capital and saw participation from Also Capital and Banner VC, Bloomberg reported. The company’s valuation was not disclosed.

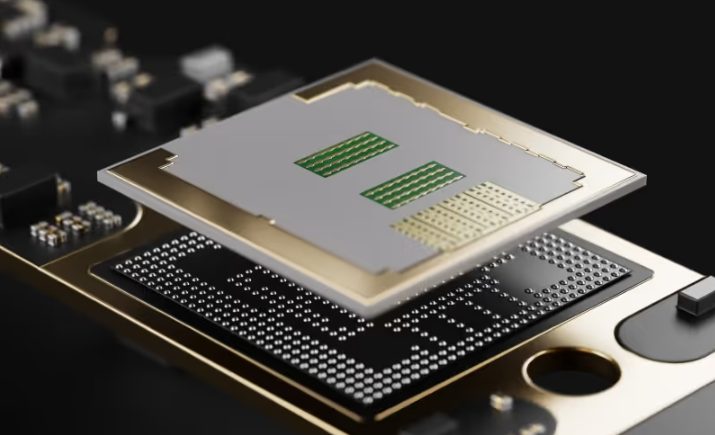

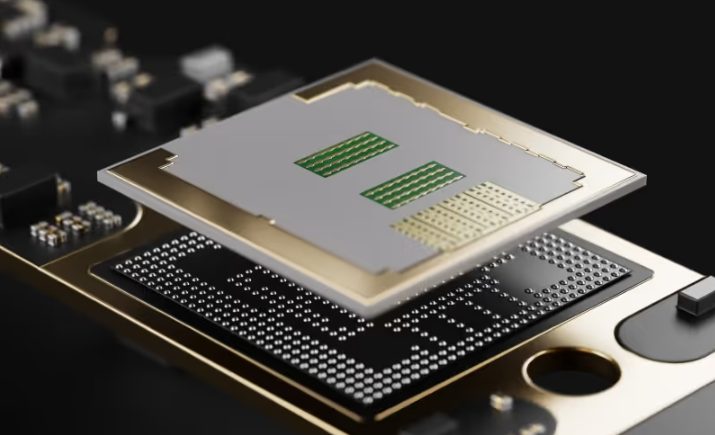

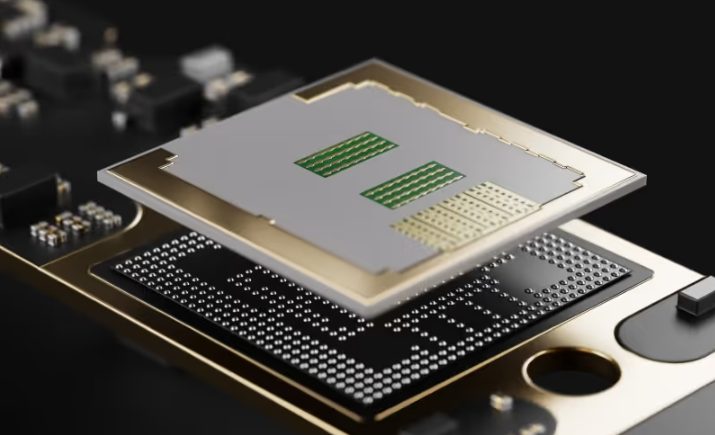

The startup’s goal is to mass-produce high-performance optical transceivers, which are devices designed to move data around data centers at rapid speeds. They work by converting optical signals from fiber or lasers into electrical signals that can be read by computers.

The co-founders told Bloomberg that they first realized the opportunity for this technology while working at SpaceX. Tasked with finding a way for Starlink’s satellites to communicate vast amounts of data in real time, they began looking at optical receivers, and quickly realized the industry’s limitations.

Optical receivers have become an essential element of modern artificial intelligence data centers, also known as “AI factories,” which support the training and inference operations of large language models. They make it possible for multiple graphics processing units and other chips to work together in unison, so AI companies can build the massive clusters their largest models require.

Traditional data center architectures are ill-suited for GPU clusters, because they were not designed for the kind of lateral, high-throughput traffic that characterizes today’s AI factories. Historically, cloud data centers have always been optimized for “north-south” traffic flows, meaning data that moves into and out of the facility.

But AI training and inference generates massive “east-west” traffic, as the GPUs are constantly bouncing data around between themselves so they can work together to tackle problems. Existing network switches, cables and interconnects were never designed to handle this kind of traffic, which is why bandwidth-busting optical transceivers have become so important.

In an interview with TechCrunch, Brashears revealed that the average AI factory typically uses millions of the devices. “Someone will brag about a million-GPU cluster,” he said. “But you have to multiply that by four or five to get the number of transceivers in that cluster.”

Optical transceivers are not new, but Mesh believes there’s an opportunity because the vast majority of the world’s devices are currently manufactured in China. The co-founders believe that’s almost certainly going to be problematic in future. Mesh proudly proclaims that its products are “made in the USA,” and that’s probably going to be extremely advantageous.

Though the transceiver market has not yet seen any trade restrictions, the GPUs and other powerful processors that fuel the AI industry certainly have. Brashears said his company is trying to get ahead of a potential national security problem. Thrive Capital Partner Philip Clark agrees. He told TechCrunch that U.S. companies can’t take the risk of having critical parts of the AI supply chain controlled by misaligned and competitive companies.

Mesh’s immediate goal is to scale up its manufacturing operation. It aims to produce 1,000 units per day by the end of the year, with a view to taking bulk orders for its products in 2027. Doing so will be challenging, because the kind of automated manufacturing techniques employed by Chinese factories aren’t common in the U.S.

Still, Ramos told Bloomberg that the company aims to set itself apart by making its optical transceivers more efficient than their Chinese counterparts. Crucially, his team has designed a transceiver that removes one of the most power-hungry components, allowing it to improve its energy efficiency by between 3% and 5%. That might not seem like a lot, but for hyperscale AI factories packed with hundreds of thousands of GPUs, it could translate to significant savings on their energy costs.

Mesh’s next step is to move beyond prototyping and testing to commercial production. At the same time, it’s going to engage with prospective customers, including large-scale data center operators and cloud infrastructure providers, in order to validate its technology’s integration and performance.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.