BLOCKCHAIN

BLOCKCHAIN

BLOCKCHAIN

BLOCKCHAIN

BLOCKCHAIN

BLOCKCHAIN

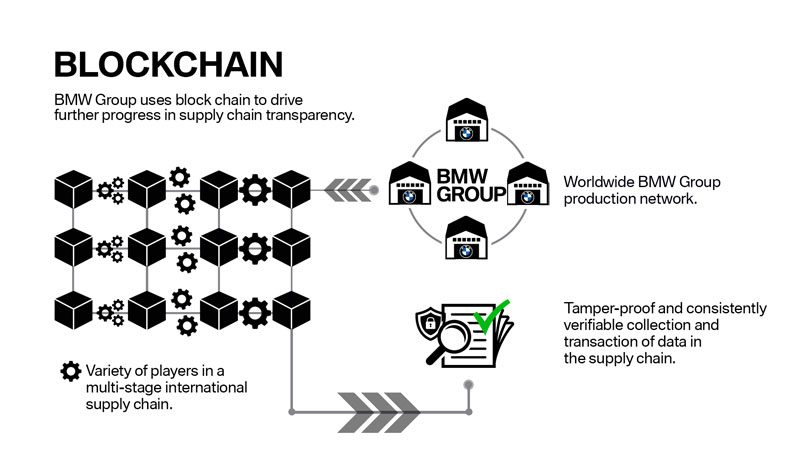

Major automotive manufacturer BMW Group announced the planned launch of its blockchain-powered supply chain management solution called “PartChain” on Tuesday.

According to the company, PartChain will launch in conjunction with 10 of its suppliers in 2020. BMW intends to use distributed ledger blockchain technology to provide transparency and traceability of components and raw materials used in the production of automobiles.

“In 2019, we conducted a successful pilot project for purchasing front lights,” said Andreas Wendt, member of the board of management of BMW AG responsible for purchasing and supplier networks. “This year, we want to expand the project to a large number of other suppliers.”

According to the BMW, automotive supply chains are highly complex ecosystems that involve numerous players at different delivery stages. All the stops in an automotive supply chain can also change rapidly according to the needs of various parts of the industry including the availability of raw materials, the supply of specific components from particular factories, and the demand for automobiles in different regions.

As a result, it has been customary for the many partners in a supply chain to manage their own data. That has created a “dark” network in which it is difficult to clearly track a component’s origin or supply route.

Blockchain technology has proven extremely useful for supply chain management. Examples include Ford Motor Co. and IBM Corp. using the technology to track cobalt for electric car batteries and Volkswagen using Minespider GmBH’s blockchain for similar raw materials tracking. Other automakers have used the technology to track cars such as Hyundai Motor Group’s partnership with Blocko Inc. to track used cars and the Mobility Open Blockchain Initiative, a consortium which includes BMW, that is field testing a blockchain-based international vehicle identification system.

Image: BMW

Blockchain networks operate by distributing a transaction ledger between many separate nodes, these nodes can be run by each company across a supply chain. Using blockchain technology, each time a raw material or component moves, goes through processing, or gets dropped off at a warehouse, a transaction representing the change gets added to the ledger. Using cryptography and the shared ledger, blockchains also provide a secure, tamper-resistant data platform that can also keep important data private while revealing only pertinent information for audits.

As a result, it is possible to use a blockchain to track raw ore from a mine to a refinement plant to a die-casting facility to the assembly of the finished product and all the way to the part’s addition to an automobile. With this level of traceability, a single part’s journey through the supply line can be tracked from end-to-end automatically without the need for manual paperwork.

“PartChain enables tamper-proof and consistently verifiable collection and transaction of data in our supply chain,” said Wendt.

The 2019 pilot of PartChain focused on part tracking, however, in the long-term BMW also expects to use the project to enable complete traceability of critical raw materials from mine to smelter.

BMW initiated the PartChain project to provide seamless traceability through the entire supply chain without the need for a separate, manual tracking system, by using blockchain technology to connect all the parts.

“This move is designed to take the digitalization of purchasing at the BMW Group to the next level,” said Wendt. “Our vision is to create an open platform that will allow data within supply chains to be exchanged and shared safely and anonymized across the industry.”

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.