INFRA

INFRA

INFRA

INFRA

INFRA

INFRA

Robert Bosch GmbH today announced plans to buy TSI Semiconductors, a major maker of silicon carbide chips.

The acquisition price was not disclosed. However, Bosch did divulge that it plans to spend $1.5 billion on upgrading TSI’s production lines. The company said that the investment will depend on federal funding opportunities and state-level economic development initiatives.

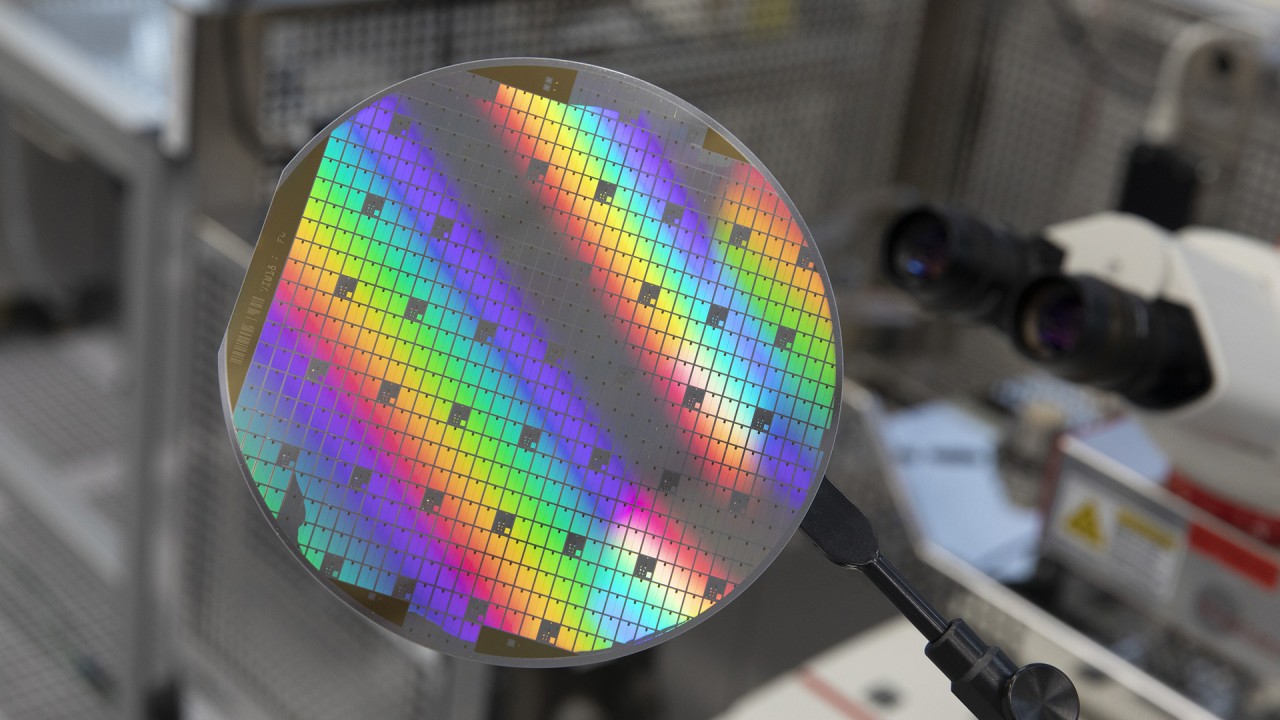

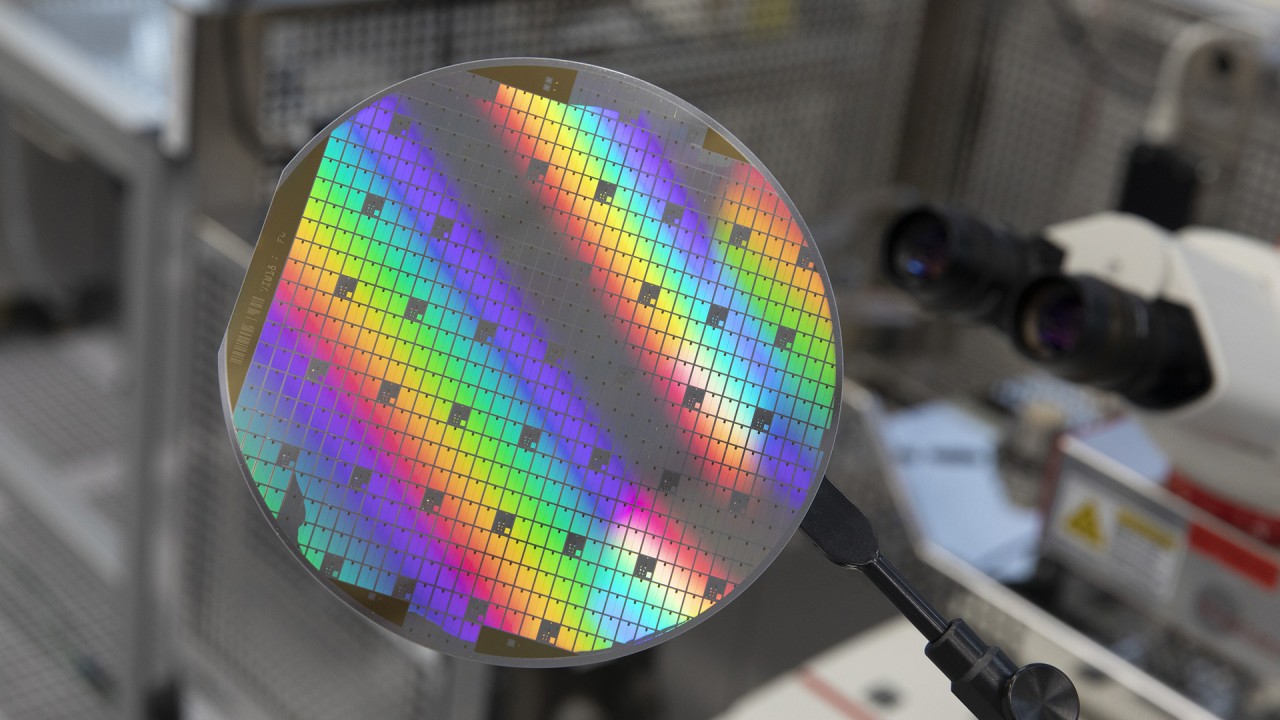

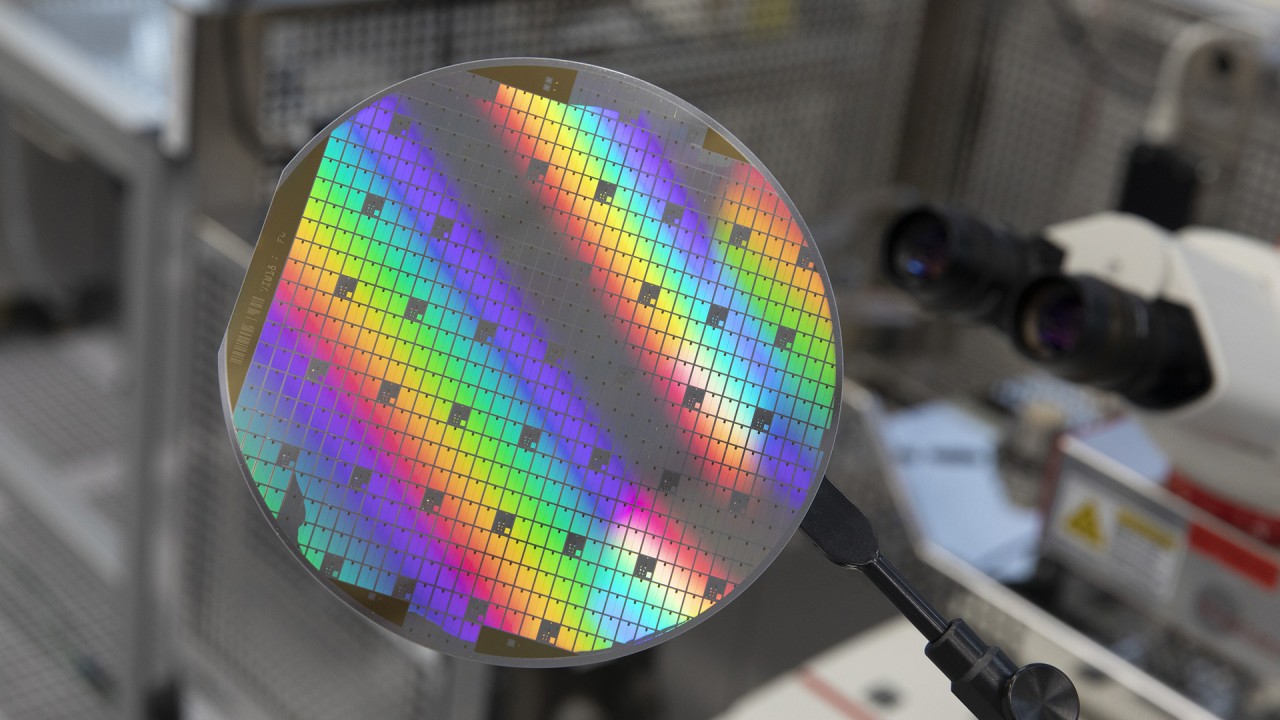

TSI manufactures chips made of silicon carbide, a compound that combines silicon with carbon. Chips made using the material can withstand higher voltage levels and temperatures than standard semiconductors. As a result, the technology is widely used in systems such as electric vehicles that must operate reliably under demanding conditions.

When electricity passes through a chip, some of the current is lost. Silicon carbide chips lose less current than standard semiconductors, which makes them more efficient. The technology allows automakers to extend the range of their electric vehicles as well as facilitate more efficient charging.

Germany-based Bosch is a major component supplier to the auto sector. The acquisition of TSI will enable the company to further grow its auto business, as well as expand its presence in other markets. Silicon carbide chips are used not only in electric vehicles but also the industrial equipment segment, where Bosch is a major player.

“With the acquisition of TSI Semiconductors, we are establishing manufacturing capacity for SiC chips in an important sales market while also increasing our semiconductor manufacturing, globally,” said Bosch Chief Executive Officer Stefan Hartung. “The existing clean-room facilities and expert personnel in Roseville will allow us to manufacture SiC chips for electromobility on an even larger scale.”

The $1.5 billion investment Bosch plans to make following the acquisition will be used to upgrade TSI’s flagship chip fab in Roseville, California. The company intends to roll out “state-of-the-art processes” for manufacturing. After the upgrade, that facility will have about 107,000 square feet of cleanroom space, or space suitable for hosting chip manufacturing equipment.

Bosch also plans to upgrade an existing silicon carbide fab it operates in Reutlingen, Germany. The company will expand the fab’s manufacturing capacity from 376,000 square feet of cleanroom space to more than 470,000 square feet.

Both the Reutlingen and Roseville facilities will make chips based on 200-millimeter silicon carbide wafers. Such wafers, which are also being adopted by a number of competing manufacturers, facilitate more efficient chip production. The two fabs are expected to begin production by late 2025 and early 2026.

The acquisition of TSI will enable Bosch to address a fast-growing market. According to the company, demand for silicon carbide chips is growing at a rate of 30% annually. By 2025, Bosch expects that each vehicle for which it supplies components will include about 25 of its internally developed chips.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.