AI

AI

AI

AI

AI

AI

Machina Labs Inc., a startup using robots equipped with artificial intelligence to manufacture metal products, today announced that it has raised $32 million in funding.

The Series B investment was jointly led by Nvidia Corp.’s NVentures investment arm and Innovation Endeavors. A number of unnamed existing and new backers participated as well. Since launching in 2019, Machina Labs has raised a total of $46 million from investors.

“This Series B funding underscores the transformative potential of merging robotics and artificial intelligence,” said Machina Labs co-founder and Chief Executive Officer Edward Mehr.

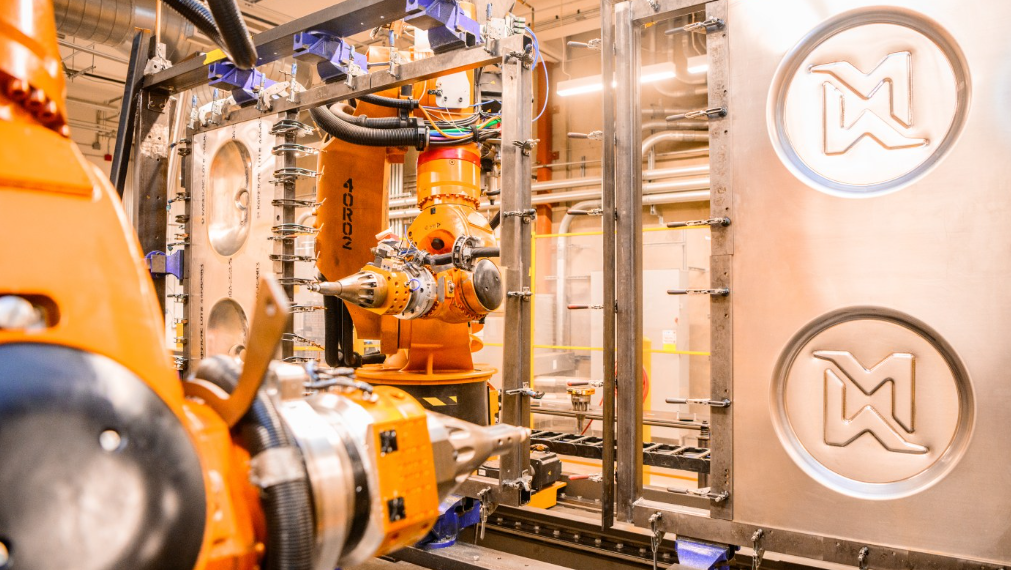

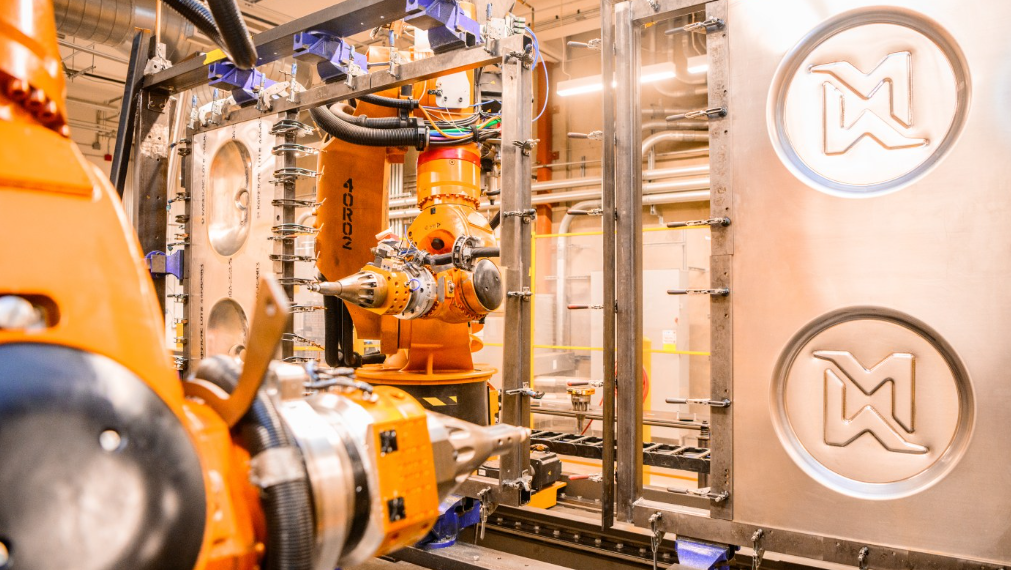

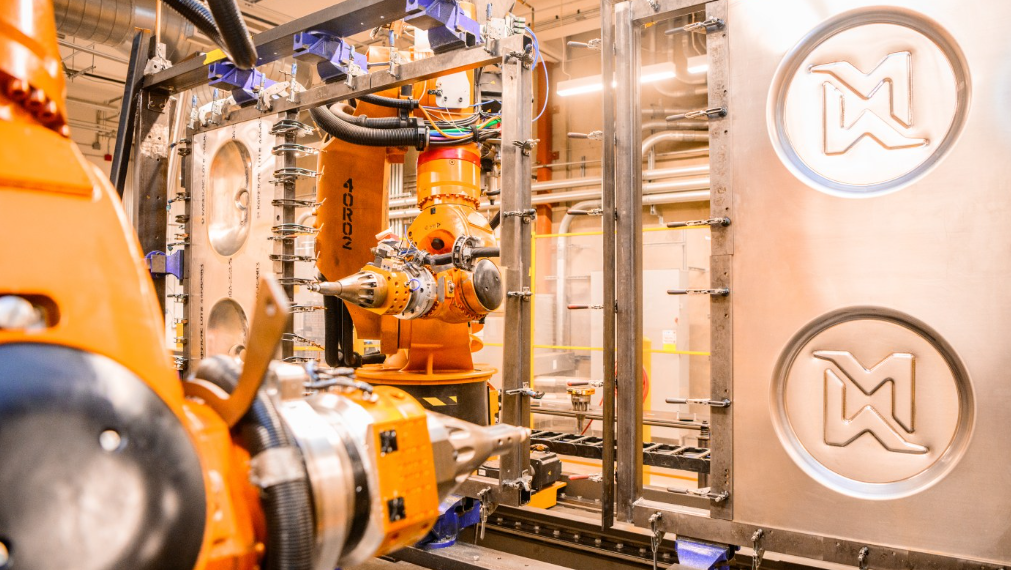

Los Angeles-based Machina Labs sells a suite of robots, sensors and software that manufacturers can use to build automated production lines. The company’s robots are geared towards making metal products. According to Machina Labs, production lines powered by its technology can manufacture metal parts up to 12 feet long and four feet deep with submillimeter precision.

The company’s robots make products out of sheet metal, or flat pieces of metal that lend themselves well to mass production. It says that its systems can work sheets made of aluminum, steel and titanium as well various metal alloys. That includes so-called superalloys, which are used in industries such as the aerospace sector because they can withstand extreme heat and pressure.

Manufacturers typically use six-axis robots in their automated production lines. A six-axis robotic arm can move its “hand” in all directions with a beeline motion, as well as rotate the hand in place. Machina Labs uses seven-axis robots, which have the same range of motion plus the ability to travel from one end of a production line to another using a mechanism such as a rail.

Each of the company’s machines is equipped with a laser scanner that it uses to collect data about the metal parts it makes. According to the company, AI algorithms leverage the collected data to compare the parts against the CAD model on which they’re based. If there are inconsistencies, the AI adjusts the production workflow to increase manufacturing accuracy.

A core selling point of Machine Labs’ robots is that they can be adapted to new tasks with relative ease. Typically, reconfiguring a robot to make a different product than the one it was originally programmed to produce takes weeks or months. Machina Labs, in contrast, says its systems can “change tools and sensors instantly”.

The company will use the proceeds from its latest funding round to finance go-to-market and product development initiatives.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.