EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

Freeform Future Corp., a startup developing 3D printers for producing metal parts, today announced that it has raised $14 million in funding.

The capital came from Nvidia Corp.’s NVentures fund and Boeing Co.’s AE Ventures. Besides providing funding, the two companies will also provide Freeform with other resources such as graphics cards. The startup previously raised $45 million from a group of venture capital firms.

Metal objects such as car engine components are mainly made using so-called CNC machines, which are essentially large power tools controlled by a computer. In some industries, manufacturers are also adding 3D printers to their production lines. Such systems require less work to set up than a CNC system and are better at producing certain types of small, complex metal components.

At the same time, 3D printers also introduce a new set of challenges. They require specialized expertise to use and produce parts at a relatively slow pace. As a result, adoption of 3D printers remains limited among manufacturers.

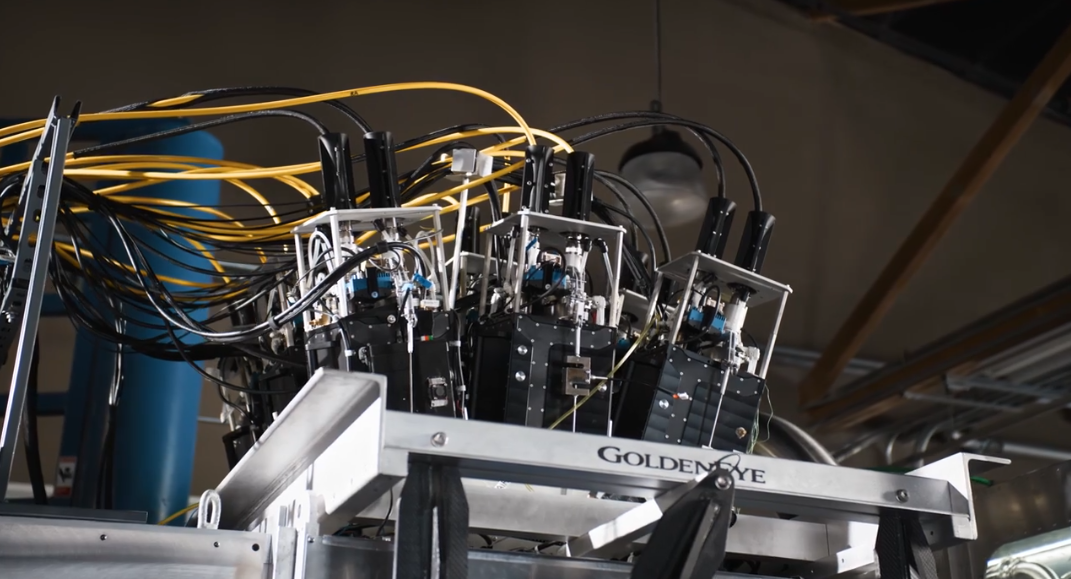

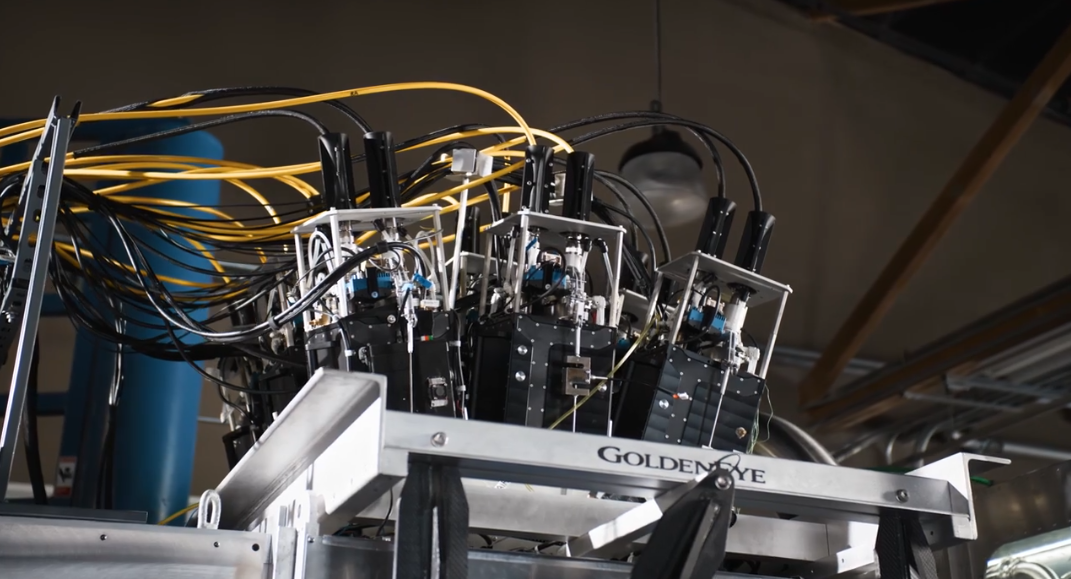

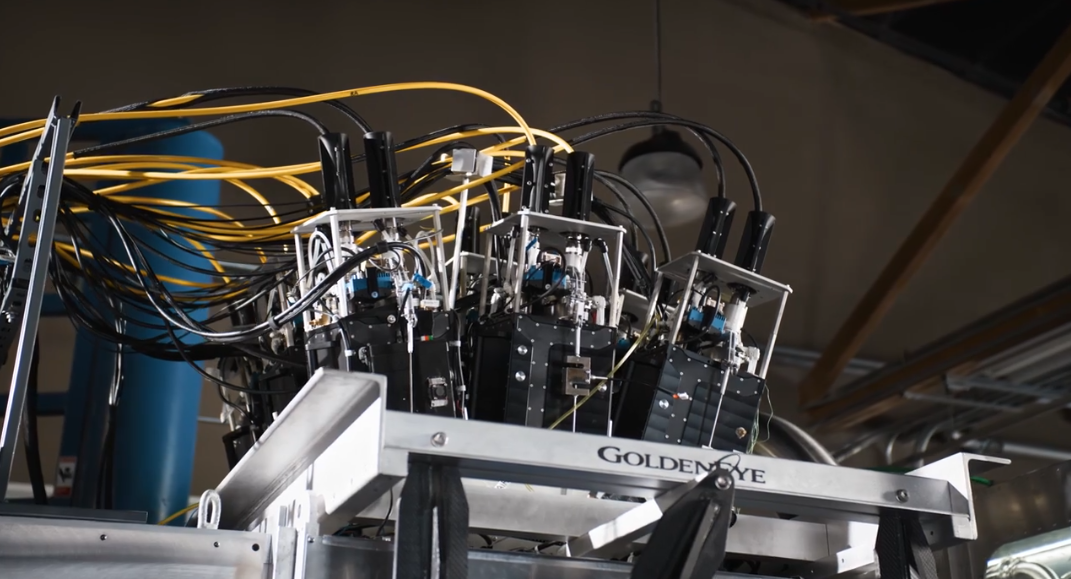

Hawthorne, California-based Freeform hopes to make the technology a more practical choice for producing metal parts. The company develops 3D printers powered by artificial intelligence software. According to the company, its AI analyzes metal parts while they’re being produced to ensure they don’t contain any faults.

Freeform runs the software on not only graphics cards but also FPGAs, or field-programmable gate arrays. Those are programmable chips that a company can optimize for a specific program to speed up that program. A manufacturer, for example, can configure its FPGAs to run the software that coordinates its production lines.

Industrial 3D printers produce parts in an internal chamber filled with metal powder. During manufacturing, this powder is melted by a laser or an electron beam generator. The heat causes the metal particles to coalesce into a single object with a structure specified by the customer.

After the initial batch of metal powder is processed, 3D printers can add more layers on top and repeat the workflow. Support structures made of the same metal as the powder are sometimes added to streamline the process. This technique makes it possible to produce parts with highly elaborate shapes.

Some 3D printers implement a different manufacturing approach. Instead of melting the metal powder, they use an adhesive liquid to turn it into a single mass. They then remove unnecessary material and shape the remainder into the form specified by the customer through a combination of pressure and heat.

Instead of selling its 3D printers, Freeform deploys them in an in-house factory that provides contract manufacturing services. Customers can order custom components without having to learn how to operate a 3D printer fleet. Additionally, they can avoid the upfront expenses associated with purchasing such hardware.

The company works with organizations in the aerospace, automotive, industrial and energy sectors. It says that it can produce thousands of parts per day for customers.

Freeform will use its new funding to add production capacity, develop a faster 3D printer and increase the number of materials that its factory can process. To support the effort, Nvidia will supply the company with H100 graphics processing units. Boeing, in turn, reportedly plans to guide Freeform through its supplier onboarding process in a partnership that could reportedly lead to part purchases.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.