EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

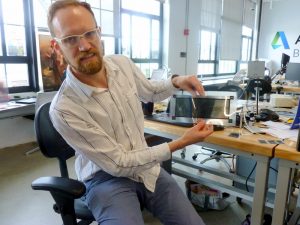

Matt Hirsch and Tom Baran have an idea that they think could revolutionize everything from the minting of money to the printing of diaper packages. The two MIT Ph.D.s have developed a way to create high-quality digital images that resemble three-dimensional holograms using consumer-grade inkjet printers.

Holographic printers cost thousands of dollars and can output only to special media. The approach that Hirsch and Baran, co-founders of Lumii Inc., have developed works on any transparent medium. That could bring the holographic authentication techniques typically used only on high-value items within reach of anybody.

Lumii’s “offices” are a bench on the second floor of Autodesk Inc.’s Build Space. It’s a 34,000-square-foot collaborative research and development workshop located in a converted former U.S. Army base in a revitalized section of the Boston waterfront. Autodesk moved into the cavernous facility in late 2016, and today it hosts 31 early-stage startups and researchers investigating new ways to apply technology to construction.

Lumii co-founder Matt Hirsch demonstrates one of the firm’s 3D images created with a standard printer.

It’s one of four such facilities run by the venerable software company, which specializes in products for computer-aided design. There’s another in San Francisco that explores new ideas in design and digital manufacturing, one in Toronto that experiments with new technologies such as virtual reality and smart devices, and a Birmingham, U.K.-based foundry that focuses on advanced manufacturing.

The technology centers are a variation on the popular technology incubator concept with a private-sector twist. The organizations that share Build Space pay nothing to be there, and Autodesk doesn’t invest in them. Instead, the company uses the opportunity to tap into the ideas incubating there that could influence the software it builds. Designers and developers from the company’s Boston headquarters four floors above routinely stop by to observe the work in progress and ask how software could make the job easier.

Autodesk’s Rick Rundell shows a time-series chart of Build Space’s first two years of residents.

“It’s a soft ROI,” said Rick Rundell, senior director of Autodesk technology centers and founder of the Boston facility. “We’re not going to get into the robotic rebar placement industry, but we might build software for companies that do.”

Some projects are challenging long-held design truisms. For example, Ori Inc., which grew out of research at the nearby MIT Media Lab, uses Build Space to develop its concept of movable living space that urban dwellers could use to transform the layout of cramped apartments dynamically. “That was a challenge for us because our software has always assumed that walls don’t move,” Rundell said.

Another team composed of researchers from Cambridge University, Architects at Perkins + Will Inc. and engineers from Thornton Tomasetti Inc. used the facility to develop several prototypes of a skyscraper made entirely of wood. Such a structure is more environmentally friendly and actually more resistant to fire, since metal fasteners are usually the element that fails first in a blaze.

Artifacts of previous projects dot the building, such as a proof-of-concept for a new type of roof constructed of strands of fiber shot out and strung together by robots, like a giant spider web. The technology could eventually replace domes and other large-space enclosures with an approach that’s cheaper, lighter and easier to assemble.

Build Space is a manufacturing geek’s dream, featuring nearly every kind of digital manufacturing device imaginable. There’s a machine that can ingest strips of coiled aluminum and spit out custom-made metal studs. The technology could not only cut the cost of delivering finished goods to a construction site but enable the size and shape of studs to be customized on the spot, eliminating days or weeks lost in placing custom orders. “The benefits of robotics come not only from faster construction but also by reducing the number of items that need to be brought to construction site,” Rundell said.

There’s a cutting machine that fires jets of gritty water at 2,800 miles per hour, slicing through solid slabs of titanium 22 inches thick. There’s a giant walk-in kiln that cures glass and fibers at 475 degrees, 3-D printers that can build concrete walls and milling machines that sculpt steel as if it were butter.

And there are robots, lots and lots of robots. Many are loaners from equipment makers that see the center as an ideal way to test new gear. On the ground floor, a team from Texas A&M University is using a robot to develop new ways to build support arches by carving pieces from a single block of material and assembling them with near-zero waste.

Architecture student William Palmer deftly maneuvers a wire-cutting arm through test blocks of Styrofoam under the watchful eye of Negar Kalantar, an assistant professor in the school’s Department of Architecture. “The facilities are amazing,” she said.

Texas A&M architecture student William Palmer guides a wire-cutting robot.

At a corner bench on the second floor, Hakim Hasan, a researcher at Perkins + Will, is using a general-purpose robot from Denmark-based Universal Robots A/S to shine a light on a tiny model of a building (pictured at top). The robotic arm and light source are programmed to simulate the precise path of the sun on any day of the year, an essential test for urban high-rise construction. “It’s a tedious process to do manually, which discourages a lot of architects,” Hasan said. “This gives them the tactile experience they like.”

Perkins + Will wants to offer robotics as a service for architects using a single machine that’s programmed to choose from a palette of customized tools to perform any simulation a building designer might need. The firm applied to Build Space to get access to the machinery it needs to fabricate those tools.

“Nearly everything other than the robot was fabricated here,” Hasan said, pointing to a table full of accessories. “It’s important to get precisely machined parts because the robot works to fractions-of-a-millimeter precision.”

Autodesk fields six to eight applications each week for space in the facility, which is available 24 hours a day, 365 days a year. Once approved, teams need only supply evidence of insurance to take a space. Some stay just a few weeks, others more than a year. And some, like Lumii, make Build Space their headquarters while they ramp up.

One reason they do is because there are so many other inventors there just like them. “Some of the discussions we’ve had with people we’d never have met can take us in a number of ways,” said Lumii Chief Executive Baran. “It gets us thinking about wild new uses of our product or new ways to find investors.”

Not all residents are startups, either. Elkus Manfredi Architects Ltd. is a 30-year-old diversified architecture firm that’s using Build Space to test new ideas for construction using locally sourced and recyclable materials. On a recent visit, Architectural Designer and 3-D Fabrication Coordinator Thomas Carrier was surrounded by blocks of hewn cork, a material that’s little-used in construction. “We want to see how we can make cork more interesting so that more clients will want to use it,” he said.

Technology firms are often accused of putting stock options and quick exits ahead of fundamental research. Build Space is a reminder that there are still some that believe in nurturing great ideas just because they’re great.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.