NEWS

NEWS

NEWS

NEWS

NEWS

NEWS

3D printing is providing an ever-increasing opportunity for industrial works to create their own parts on demand, but so far most of those parts had to be made out of polymers and some metals. Recently, however, researchers have discovered additive printing techniques that allow for ceramic as a material for custom partsaqs. This opens up an entire horizon for print-on-demand parts rated for the rigors of high heat, pressure or other hazards.

He patted a case in his lap. Inside was a section of pipe, fresh from the Industrial Works Department, 3D printed to specifications stored in the Paradigm Database. This work detail had been dispatched because the sensors in that section of pipe had shown increased pressure loads and higher stress. Combined with other sensor measurements and historical data from pumps and pipes downstream showed an increased probability of failure and soon.

— Excerpt from The City of Paradigm, novel by Kyt Dotson, © 2014

One might think that we are far from using 3D-printed materials for industrial use cases, but you’d be surprised as to how far the market has evolved. There are now various types of filaments that can be used for 3D printing depending on your need or project. There are magnetic, porous, water-soluble, temperature-resistant, hard plastic, soft plastics and even some that are made from beer dregs that deliver end products that look like wood.

Modern day 3D printing techniques have long been used in industrial applications for rapid prototyping or production of items, but a new ceramic printing process promises printed objects of extreme durability, which will be a massive boon for industrial design.

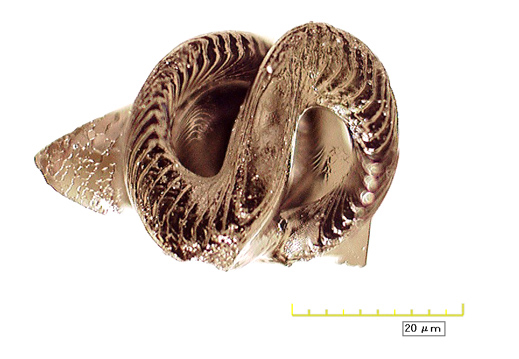

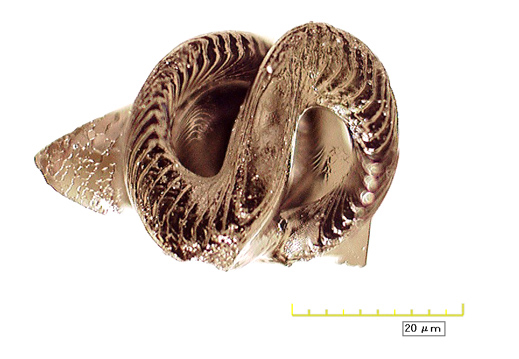

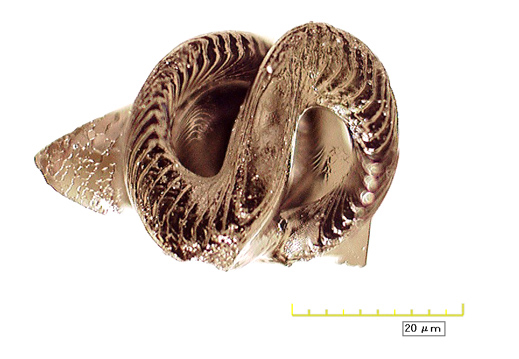

Researchers at HRL Laboratories LLC have discovered a way to 3D print durable parts in the form of ceramics, a material with high strength, resistance to heat, chemical degradation and friction. To create ceramics, a new resin made of pre-ceramic polymers are heated at high temperatures. The researchers demonstrated that the resin is compatible with stereolitography, wherein a liquid polymer is used in conjunction with a laser beam to create objects layer by layer. The resin is also compatible for use with a specialized technique utilizing ultraviolet light and patterned masks to create complex 3D structures resembling lattices at speeds 100 to 1,000 times faster than stereolithograply. After the parts have been printed, it must be subjected to heat to turn the pre-ceramic polymer into ceramic.

According to HRL Labs senior scientist Tobias Schaedler, because of this new type of polymer, there are now two new useful ceramic parts that can be printed. The first implementation is a large, but lightweight lattice structure used as heat-resistant panels or other exterior parts of airplanes or aircrafts, and the second is a small, intricate part used for electromechanical systems or parts of jet engines and rockets.

Defense Andvanced Research Project Agency (DARPA) supported the research of this resin and has now funded a lab to develop a ceramic aeroshell that can be used as a shield for spacecraft or hypersonic aircraft from heat, pressure and debris.

According to DARPA’s director or Defense Sciences Office Stefanie Tompkins, ceramic foams can be used for the aeroshell for its thermal properties, but it lacks mechanical properties that would allow it to be suitable for use in load-bearing structures. The ceramic created in the HRL Labs are 10 times stronger than the ceramic foam because of the lattice structure, making it ideal for industrial use.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.