EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

EMERGING TECH

The German industrial manufacturing company Siemens AG today announced a partnership with Nvidia Corp. to transform industrial automation using hyper-realistic real-time 3D graphics by enhancing “digital twins,” or virtual models of the real world that simulate manufacturing applications accurately.

The partnership was announced at the Siemens’ Accelerate virtual event by Roland Busch, president and chief executive of Siemens, and Jensen Huang, founder and chief executive of Nvidia.

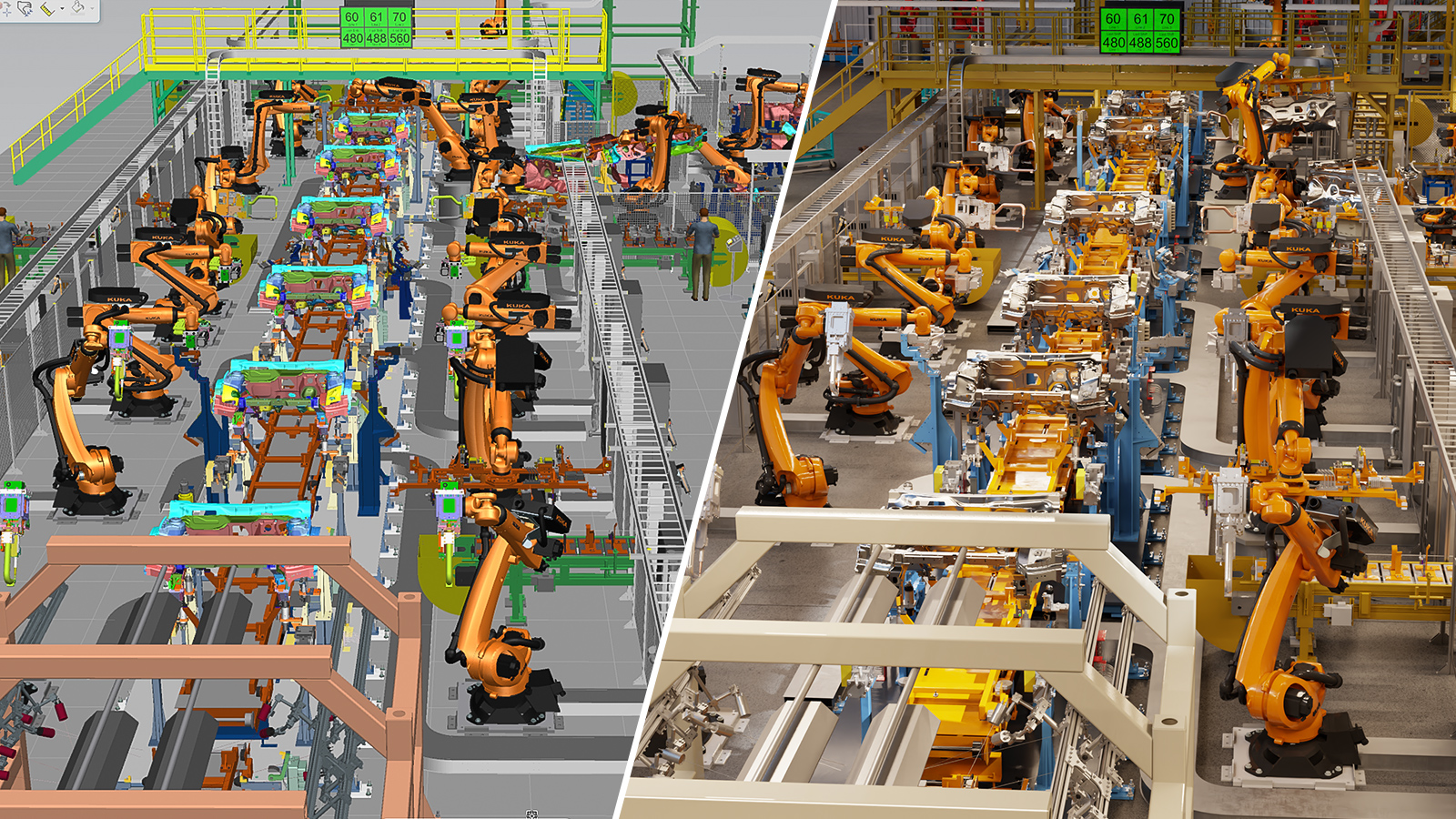

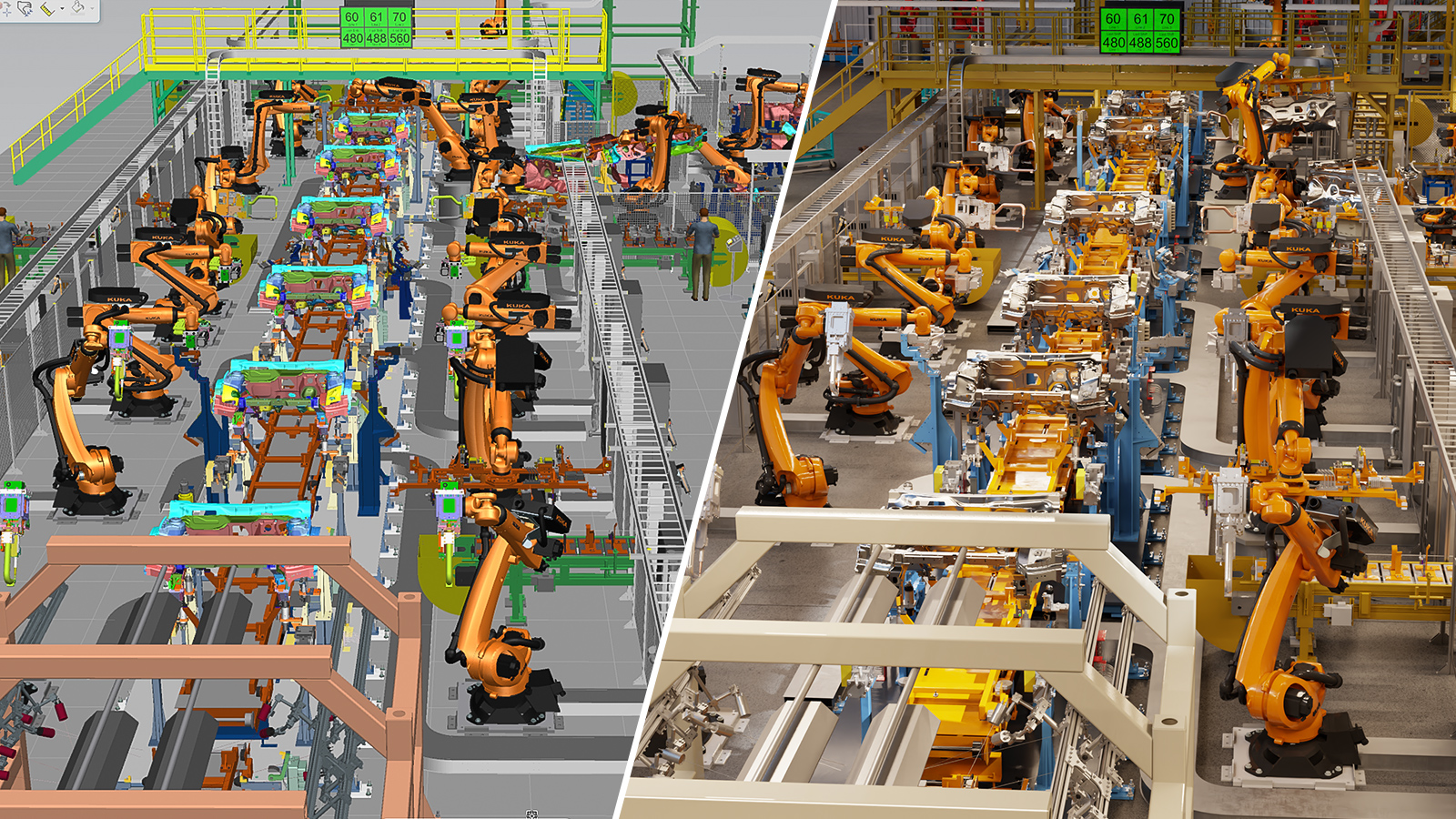

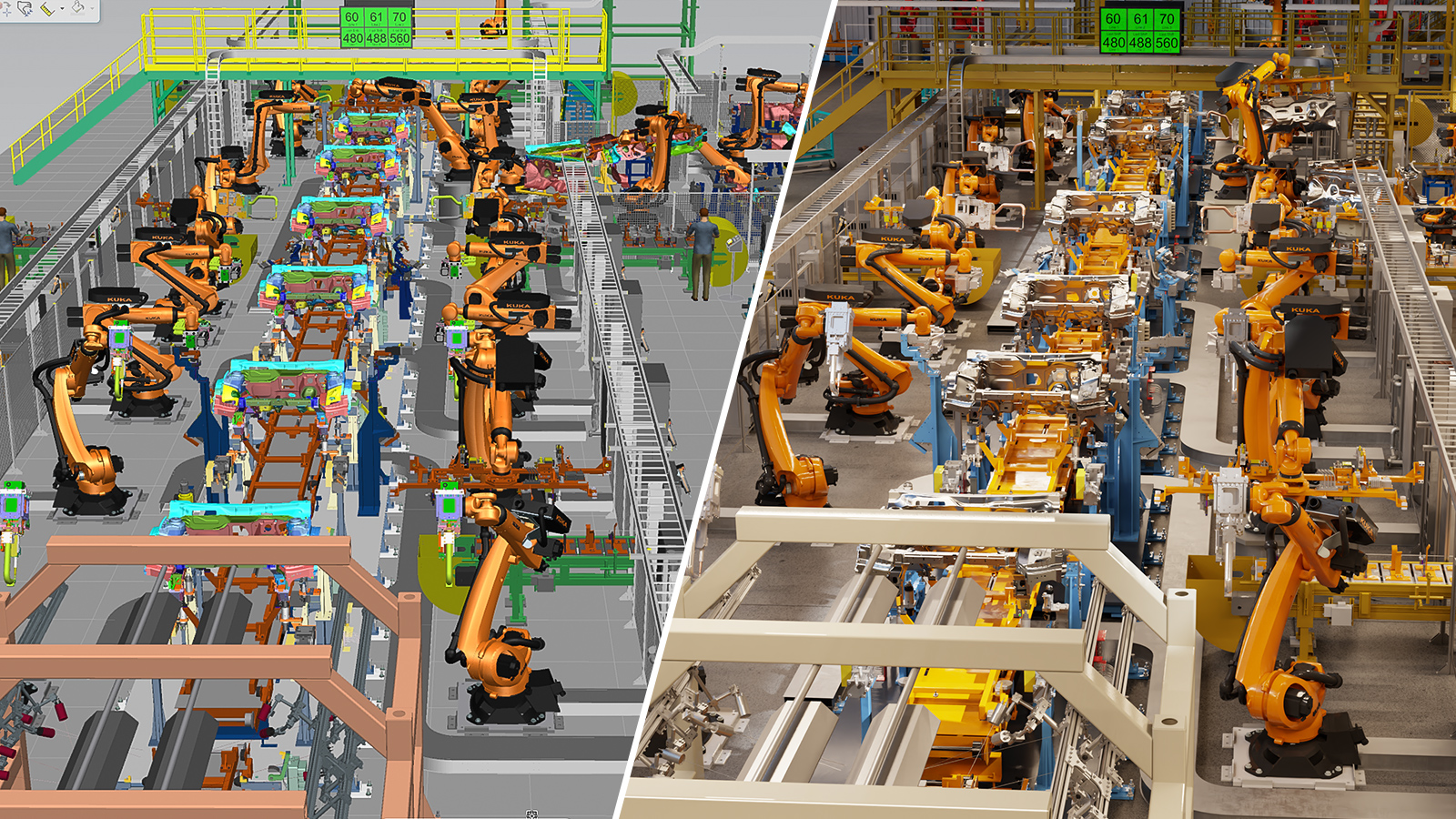

Nvidia will provide Siemens access to Omniverse, the chipmaker’s platform for 3D design and collaboration that uses artificial intelligence to create high-fidelity simulations of the real world. That will help the company generate highly realistic simulations of its industrial manufacturing automation systems in order to produce more accurate digital twins, the companies said.

Digital twins can be used to virtually recreate real-world simulations so that different “what if” manufacturing scenarios can be easily tested out without needing to build entire factory floors or designs. It greatly enhances the speed of efficiency, automation and design by taking away the need for creating numerous physical prototypes by allowing the creation of physics-based models using real-time with high confidence.

“Siemens and Nvidia share a common vision that the industrial metaverse will drive digital transformation,” said Huang. “This is just the first step in our joint effort to make this vision real for our customers and all parts of the global manufacturing industry.”

Alongside this partnership, Siemens also announced the launch of Xcelerator, an open platform of partner ecosystems designed to accelerate digital transformation for businesses by providing key components such as information technology infrastructure, internet of things enabled hardware, software and digital services, and access to Omniverse as well.

“The connection to Siemens Xcelerator will open Nvidia’s Omniverse and AI ecosystem to a whole new world of industrial automation that is built using Siemens’ mechanical, electrical, software, IoT and edge solutions,” said Huang.

“Internet of things” sensors inside of machines inside factories can feed tremendous amounts of data for digital twin simulations allowing for even greater accuracy. That also enables use cases that would be difficult without access to a virtual world, or metaverse.

Example use cases include changing the factory floor layout in order to test out different configurations to see how it would affect the movement of workers, and judging their safety around moving robots. It can also be used to examine data from sensors to determine the origin of vibrations or visually find the origin of failures by looking through virtual physics models.

“Photorealistic, physics-based digital twins embedded in the industrial metaverse offer enormous potential to transform our economies and industries by providing a virtual world where people can interact and collaborate to solve real-world problems,” Busch said. “Through this partnership, we will make the industrial metaverse a reality for companies of all sizes.”

Siemens has been using digital twin technology to assist its own customers to boost productivity for over a decade and the company believes the addition of Nvidia’s Omniverse and its high-fidelity, real-time AI-driven physics simulation will greatly enhance its current solutions.

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.