AI

AI

AI

AI

AI

AI

Once a behind-the-scenes function, supply chain optimization has become a strategic imperative in today’s volatile business climate. From pandemic fallout to global trade disruptions, enterprises have learned that resilient, automated supply chains are critical to survival — and to long-term competitiveness.

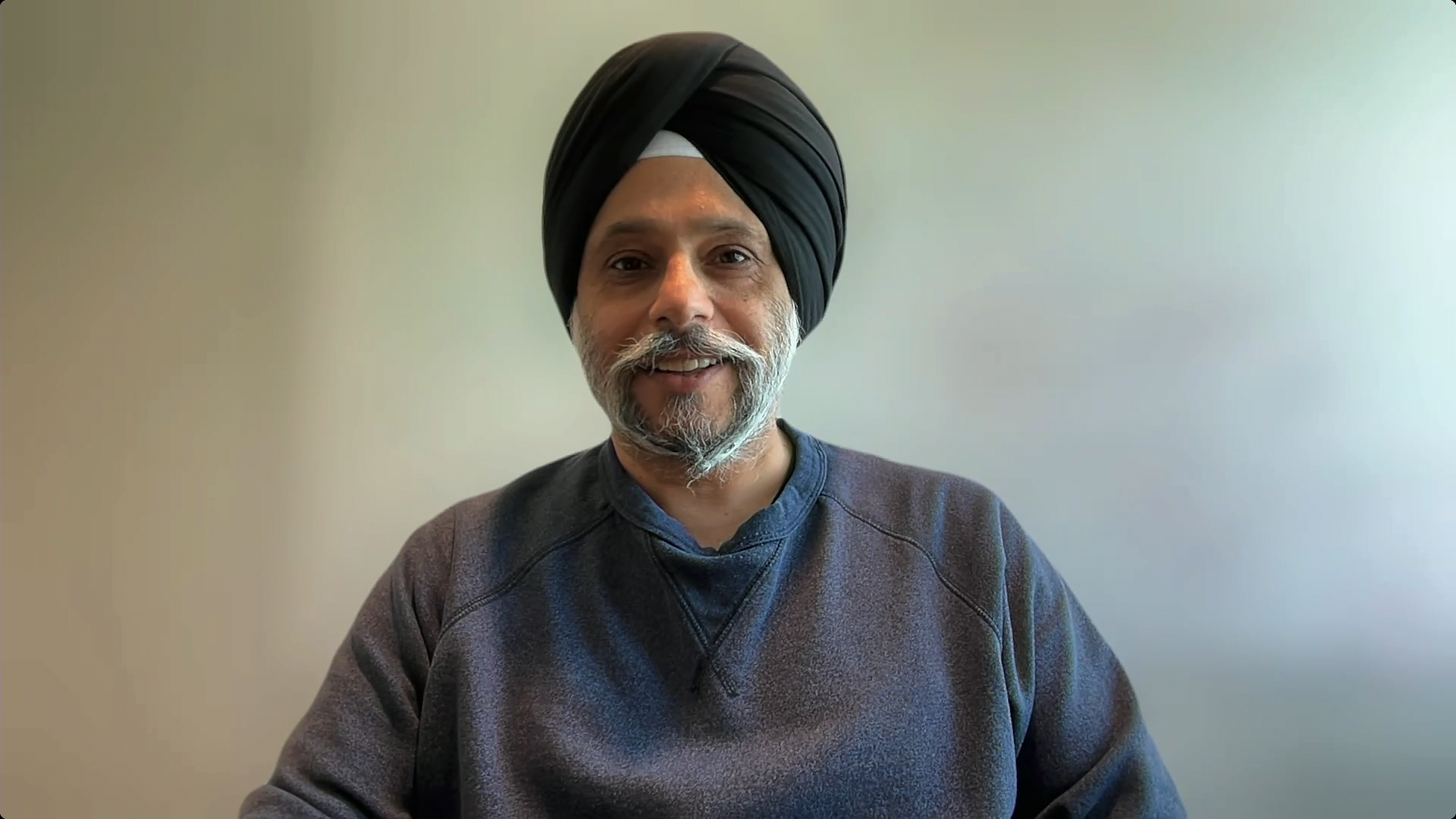

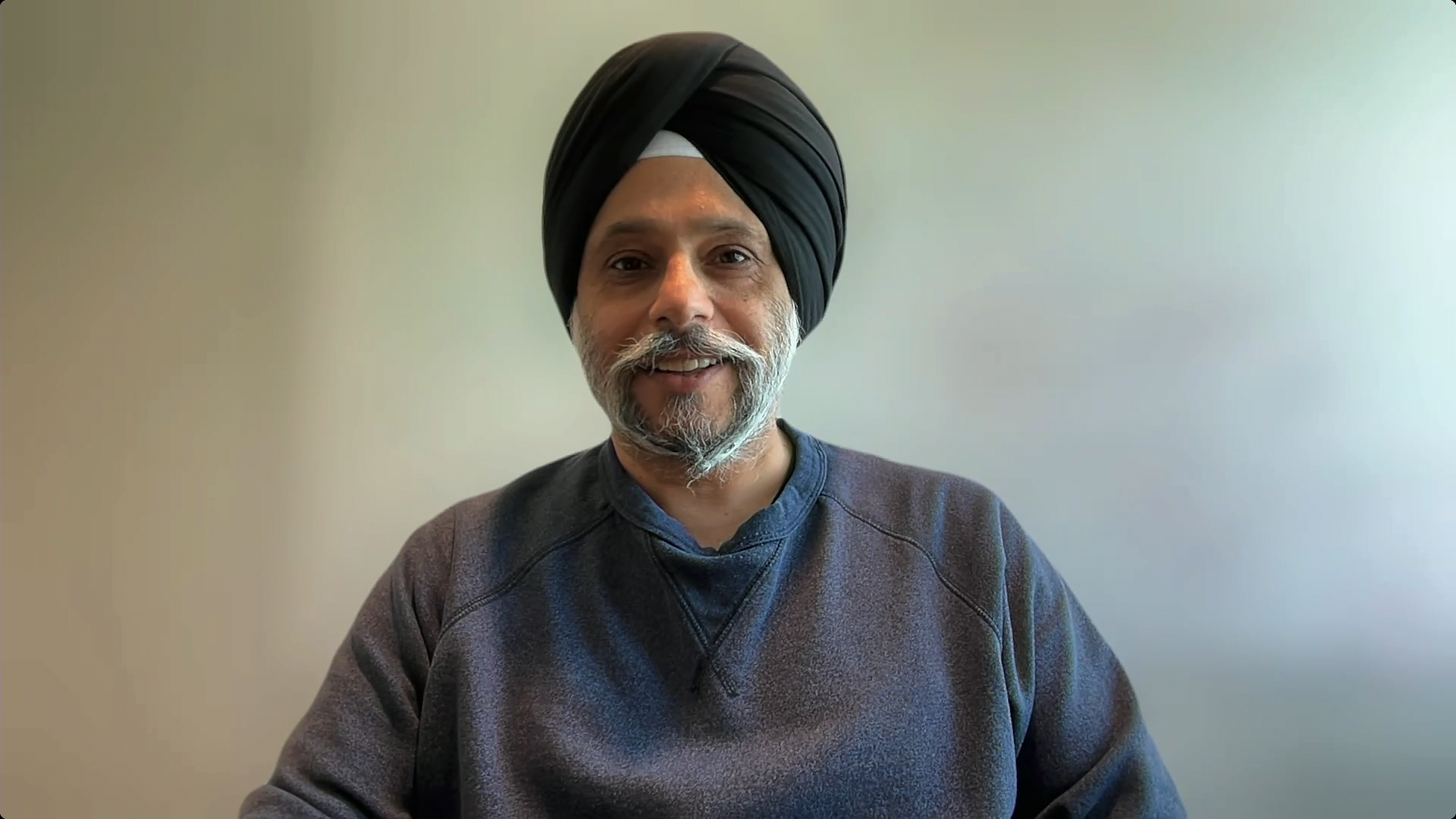

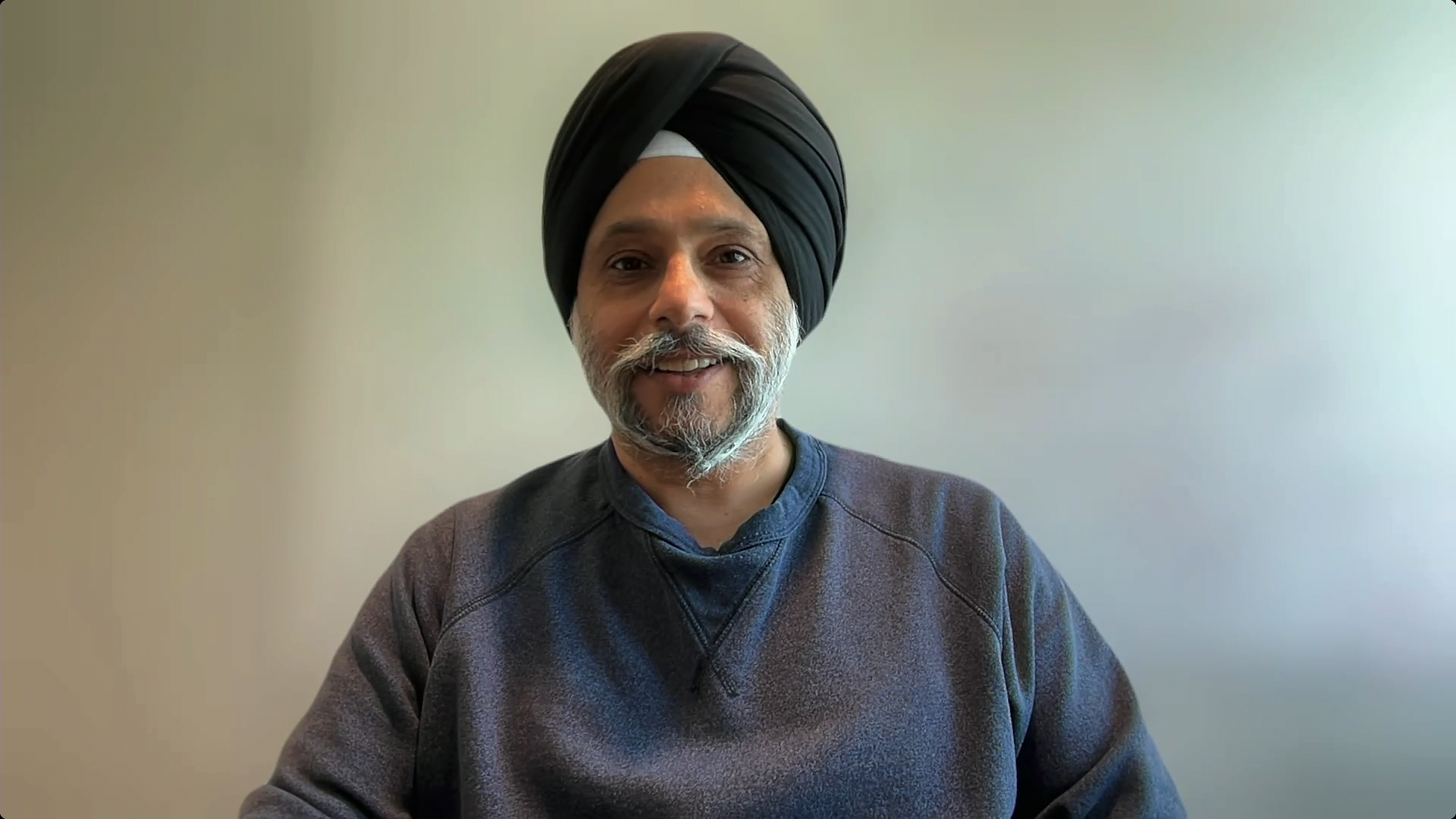

Amid this uncertainty, Blue Yonder Group Inc. is helping companies regain control. By combining AI-driven insights with real-time execution, Blue Yonder is enabling smarter, faster decisions across complex operations — reducing risk, waste and reaction time at scale, according to Gurdip Singh (pictured), chief product officer of Blue Yonder Group Inc.

“We’re living in a world of uncertainty,” Singh said. “It’s hard to manage that uncertainty, and companies are looking for all kinds of tools and capabilities not just to try and figure out what to do in the here and now, but take the time to figure out what that midterm and long-term strategy is going to be across all their business functions. And Blue Yonder is well-equipped to help them manage it.”

Singh spoke with theCUBE’s Dave Vellante and George Gilbert during the “AI and the Autonomous Supply Chain” interview series on theCUBE, SiliconANGLE Media’s livestreaming studio. They discussed the mounting trends transforming supply chain strategy, technology and planning. (* Disclosure below.)

In today’s environment, speed isn’t just about moving fast — it’s about moving intelligently. Beyond velocity alone, precision in decision-making separates winners from losers in supply chain optimization. The real competitive advantage lies in reducing the time gap between deciding to act and executing that action, according to Singh.

“People were very used to working with a single number and a simple set of assumptions,” he said. ” All of a sudden, they’re having to live in this world where they need to be able to evaluate all of the risks and opportunities that their business faces to do that at machine speed, and with precision, and to make sure that, when they do come to a conclusion, that it is something that their suppliers and carriers can also agree with.”

For example, a major retailer and Blue Yonder customer with billions in revenue faced disruptions that forced them to hold extra inventory — an expensive stopgap that cost $9.1 million per day at a single site, according to Singh. With Blue Yonder’s AI and real-time analytics, the company minimized that decision-execution gap, reducing waste, improving efficiency and responding to change with agility.

“If you can squeeze the time out of the lag between when you decide you want to do something to when it gets done, you take out the oxygen from the room that feeds that uncertainty,” he said. “In many ways, the speed at which an enterprise needs to operate is essentially the speed that will close down that gap between deciding and acting, which happens to be pretty large.”

Supply chains have outgrown traditional ERP systems designed for static, internal operations. Simply put, legacy architectures are poorly suited to today’s real-time responsiveness and cross-functional integration demands. As such, the four technological pillars driving Blue Yonder’s modernized approach include the data cloud, knowledge graph, event-driven decision-making and the network ecosystem, Singh explained.

“The second one is the knowledge graph that allows you to define semantically, in a human-understandable manner, all the different constraints and relationships that exist between the data so that it can be brought to bear,” he said. “The reason it’s important for this to be in a human-readable manner is because … businesses are not static. ERPs were mistaken when they set it up in that very static mode that takes forever to change.”

Here’s the complete video interview with Gurdip Singh, part of the “AI and the Autonomous Supply Chain” interview series:

(* Disclosure: Blue Yonder Group Inc. sponsored this segment of theCUBE. Neither Blue Yonder nor other sponsors have editorial control over content on theCUBE or SiliconANGLE.)

Support our mission to keep content open and free by engaging with theCUBE community. Join theCUBE’s Alumni Trust Network, where technology leaders connect, share intelligence and create opportunities.

Founded by tech visionaries John Furrier and Dave Vellante, SiliconANGLE Media has built a dynamic ecosystem of industry-leading digital media brands that reach 15+ million elite tech professionals. Our new proprietary theCUBE AI Video Cloud is breaking ground in audience interaction, leveraging theCUBEai.com neural network to help technology companies make data-driven decisions and stay at the forefront of industry conversations.