AI

AI

AI

AI

AI

AI

Manufacturing process management software provider Retrocausal Inc. jumped onto the generative artificial intelligence bandwagon today, announcing the launch of its new LeanGPT service.

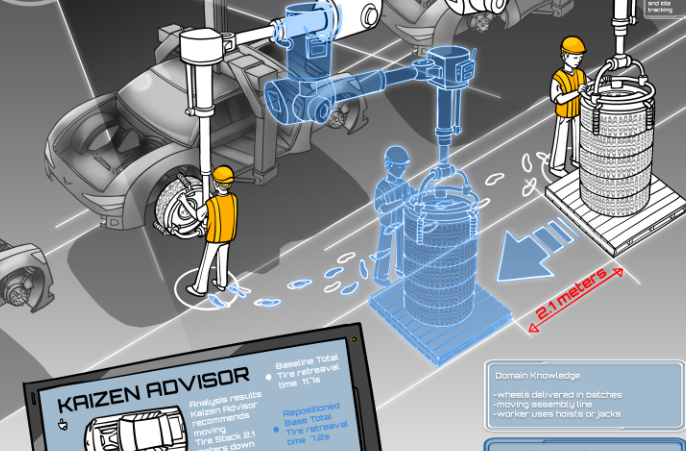

LeanGPT is a collection of proprietary foundation models that are specifically designed for the manufacturing domain. It powers a new application called Kaizen Copilot, also announced today, which is meant to assist industrial engineers in designing and continuously improving manufacturing assembly processes.

According to Retrocausal, Kaizen Copilot gathers intelligence from the company’s computer vision-based internet of things shop floor analytics platform Pathfinder. It works by autonomously accessing Pathfinder through an application programming interface. That allows it to observe factory floor activity through computer vision and IoT sensors. It also gathers insights from a company’s internal knowledge bases, before computing everything and offering recommendations on how manufacturing processes can be improved.

Kaizen Copilot is being made available as a tablet application, so engineers can access it as they navigate the factory shop floor. The app further assists engineers by embedding contextual knowledge of different aspects of the manufacturing operation, and by gathering feedback from workers on problems they experience and the solutions they come up with.

Retrocausal said industrial manufacturing processes are traditionally designed and optimized by human engineers, using a combination of domain expertise, organizational knowledge and manual observations such as time studies, ergonomics assessments and yield estimates. Kaizen Copilot promises to aid engineers in every aspect, reducing their workload and improving knowledge sharing and analysis.

“We trained Retrocausal’s generative AI LeanGPT models on specialized knowledge needed for manufacturing,” said Chief Executive Dr. Zeeshan Zia. “Using our new LeanGPT-powered Kaizen Copilot application with our Pathfinder floor analytics platform gives industrial engineers all the information they need to excel in their roles, including domain expertise, organizational knowledge, and automated process observations, eliminating the need for tedious field studies or combing through unwieldy knowledge bases.”

The company said it has already begun piloting Kaizen Copilot with a number of Fortune 500 automotive, appliances, medical devices and electronics manufacturers, and early results have been encouraging. For instance, first-time yields have been improved by 20%, Retrocausal said, while scrap costs due to assembly mistakes have fallen by 75%. Operator training times have also been improved by 44%, the company said.

Holger Mueller of Constellation Research Inc. said Retrocausal appears to have found yet another valid use case for generative AI, integrating it with shop floor manufacturing operations to make the lives of industrial engineers easier. “The first few months will be telling, showing us how much potential this technology has to transform industrial engineering processes,” he said.

Zia stated his belief that LeanGPT and Kaizen Copilot will have a significant impact on the process management industry. “Instead of starting a new assembly line at 65% yield, engineers can now obtain concrete guidance on how to push yield to 95% from day one,” he promised.

THANK YOU